|

|

|

|

Carbon sequestration in the Pacific Northwest:

a model

|

by: Ana Carolina Manriquez

Program Authorized to Offer Degree:

Table of Content** Back to the RTI Theses page **

List of Figures

List of Tables

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

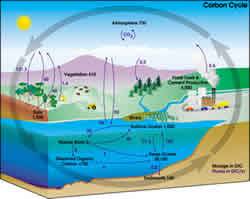

| Figure 1. The carbon cycle on Earth. Illustration from NASA Earth Science Enterprise |

Understanding the factors and processes driving and influencing the cycle of carbon in a particular ecosystem is critical to achieve proper management of the aboveground biomass and soil organic matter, whether it is for reducing greenhouse gas emissions or improving soil quality.

2.1. Forest Ecosystems

Forest ecosystems have essentially three carbon pools: the living

biomass, detritus (debris from dead plants and animals) and soils.

Soils contain almost twice as much carbon as the aboveground vegetation

and the atmosphere carbon combined (Brady 1996). Through the decomposition

and the accumulation of organic matter, soils have a major effect

on the regulation of the carbon cycle. When soil and aboveground

organic matter decline, atmospheric carbon increases, with global

consequences, such as the greenhouse effect. Potential mechanisms

for reducing net carbon emissions through increased carbon sequestration

include the forest ecosystem together with the forest socio-economic

system, with both of those systems dynamic's affecting the carbon

cycle. Conservation and adaptive management of existing forests,

the establishment of new forests (forest ecosystem level) and the

substitution of fossil fuel based energy and products by wood biomass

(forest socio-economic system) could further increase the fixation

of carbon from the atmosphere (Kohlmaier et al 1998).

Forests store carbon as they accumulate biomass, but forests are

also commercial sources of timber and wood fiber. In most carbon

accounting budgets, forest harvesting is usually considered to cause

a net release of carbon from the terrestrial biosphere to the atmosphere

(Houghton et al 1983, Harmon et al 1990). As the debate about controlling

or mitigating atmospheric carbon dioxide concentrations moves from

the study of the scientific issues to a search for practical solutions,

a central question becomes whether commercial use of forests could

be managed to contribute to terrestrial sequestration of carbon.

Can forest management practices be developed so that they meet the

multiple goals of providing wood and paper products, economic returns

from natural resources, and also sequester carbon from the atmosphere?

In managed forests, the amount of additional carbon sequestered

will be determined by three factors: the increase of standing carbon

biomass due to land use changes and increased productivity, the

amount of carbon remaining below ground at end of rotation, and

the amount of carbon sequestered in products and energy, including

their disposal (Johnsen et. al. 2001).

As stated previously, forests represent a huge storage of carbon

since they hold about 80 % of the carbon fixed in the living biota,

and much interest and effort has been put into their study, because

of the possibility of being directly altered by human activity (Apps

& Price 1996). The role of forests, as sink and sources of carbon

in the carbon cycle, is not static at any spatial or temporal scale.

Temporal changes in the forest ecosystem carbon pools are mainly

driven by the dynamics of the carbon pools. Keeping track of the

ecosystem processes, including population dynamics, is a crucial

part of the carbon assessment. This assessment should be done at

the stand level, which is believed to be the appropriate scale for

such analysis (Apps & Price 1996; Harmon 2001). Forest ecosystems

are complex, dynamic and diverse. Forest stands can be complex,

dynamic and diverse. They all have however, three carbon pools:

the living biomass, detritus and soil pools. All of these components

have a role in the carbon cycle dynamics. The soil, a natural body

of organic and inorganic materials and living forms, provide the

substrate for plant growth. Detritus, the debris from dead plants

and animals, is a source of storage as well as a source of food.

The live biomass, which includes above and below ground pools, composed

of coarse and fine roots, understory and canopy, captures carbon

dioxide while releasing oxygen, and also respires, releasing part

of the carbon dioxide previously absorbed.

A more detailed literature review will be given first for soil,

followed by above and below live biomass. Lastly, the detritus component

will be explored, including plant debris (litter fall) and harvest

residuals (slash).

2.1.1 Soils

Conversion of natural to agricultural ecosystems has lead to drastic

perturbations in the processes governing the soil organic carbon

dynamics. Deforestation, biomass burning, plowing, residue removal,

fertilization and single crop cycles have been depleting the earth's

soils in most agroecosystems by 50 to 70% (Lal 1995). The effects

of forest management on carbon soil storage are not as clear nor

as well understood as in agricultural systems. Estimated carbon

storage in below-ground components is known and has been measured

(Brady 1996), but it is mostly how harvesting and management affects

the soil carbon where knowledge is lacking.

Soil carbon has been found to be strongly dependent on the stand

composition and climate (Schlesinger 1977), therefore very hard

to model. Organic carbon in the root zone accounts for approximately

2/3 of the carbon in terrestrial ecosystems worldwide (Post et al.

1982). It is less responsive to harvest than the litter fraction

because of its long residence time. Turn over rates encompass a

large range. Post et al (1982) estimated a turn over rate of 0.00083

per year, although faster turn over rates have also been shown:

0.013 per year (Gardner & Mankin 1981) and 0.025 per year (Schlesinger

1977).

Harvesting can have a significant increase or decrease effect on

forest floor biomass, mostly based on how much slash is left behind

after the operation (Johnson 1992). The majority of studies however,

showed little or no change in the soil mineral carbon after harvest,

with less than 10 % increase or decrease (Fernandez et al., 1989;

Johnson et al., 1991; Aztet et al, 1989, Huntington and Ryan, 1990;

Alba and Perla, 1990; Lawson and Taylor, 1990; Raich 1983). Exceptions

are usually found after harvesting in tropical areas, where soils

are poor and the environmental condition are proper for rapid decomposition.

Houghton et al (1983) developed a global carbon model, in which

the assumption is that after forest harvest, tropical, temperate

and boreal ecosystems loose 35, 50 and 15 % of litter and soil carbon.

Harmon et al (1990) assume no change in soil carbon although noted

that most probably soil organic matter would decrease with intensive

forest management.

Fire, be it a prescribed or a wild fire, will reduce the carbon

and the overall floor biomass, the effects depending primarily on

the intensity of the burning, with the upper 15 cm., the surface

soil, most readily influenced by land use and soil management. In

the Pacific Northwest, a study found significant losses of floor

biomass and nitrogen (40%) after a wildfire (Grier 1975). Another

study, this time on broadcast burning, found a decrease in soil

carbon (20-30%), with an equal or higher increase in the soil carbon

almost two years after the prescription (40-70%) (Macadam 1987).

Carbon soil can be increased with fertilization, because of its

effect on primary productivity. Effects of nitrogen fixation and

fertilization on soil carbon have given results on carbon soil increasing

from 30 to 100 % depending on the site and the species mix composition

(Alnus rubra and Ceanothus spp.) (Binkley 1983; Binkley et. al.

1982). Despite all the unknowns and uncertainties of soil carbon

dynamics and management impact on those dynamics, the commonly held

assumption of soil carbon losses of 30-40% (Musselman and Fox 1991)

after harvesting was not corroborated by the literature review.

2.1.2 Above ground living biomass

Different studies present a dichotomy on aboveground biomass dynamics,

with some suggesting aboveground components can be a net sink (Delcourt

& Harris 1980, Oliver et. al. 1990) or a net source (Houghton

et. al. 1983; Harmon et. al. 1990) of carbon. Both cases are correct.

The analysis and assertions on what an ecosystem's carbon is or

will become under a certain line of management will depend on what

was the state of the ecosystem before any management was conceived.

Furthermore, it will depend on how extensive is the spectrum under

which carbon cycling is considered. For example, Harmon et al (1990)

argued that the conversion of old-growth forests to younger forests

under current harvesting and use conditions has added and will continue

to add carbon to the atmosphere, even when considering long term

products such as lumber. Oliver et al (1990) found similar results

at the forest ecosystem level, but further argued the conversion

of old growth to managed stands is negligible when compared to the

addition of carbon by the burning of fossil fuels. Similar results

were found by Schlamadinger and Marland (1996). This is why it is

very important to establish first and foremost the spectrum under

which the carbon accounting story will be evaluated. Nobody would

deny that an old growth stand stores more carbon at the forest level

than a younger stand, and that the younger stand has a greater primary

productivity, with higher rates of yearly uptakes of carbon. With

these differences taken into consideration, the above ground living

biomass is further analyzed.

In the development of a forest, the foliage, litter fall, net primary

production and nutrient accumulation in above ground tree components

usually reach a plateau at the stem exclusion stage (Tadaki 1966,

Gessel & Turner 1976, Oliver 1981, Sprugel 1985). This trend

seems to be true for Douglas-fir as well (Turner & Long 1975)

and directly impacts the development of biomass through time in

the different components.

The distribution of standing forest biomass in representative stands

in the Pacific Northwest region has been previously estimated (Grier

& Logan 1977, Keyes 1979, Edmonds 1980, Vogt et al 1980, Gholtz

1982, Cooper 1983, Keyes & Grier 1981, Santantonio & Herman

1985, Vogt et al 1986, Edmonds 1987). The total biomass and forest

carbon will depend on the stand conditions, its age, density, species

composition, etc. However, the patterns of biomass distribution

in conifer stands of the forests of the Pacific Northwest are very

similar and roughly as follows: 65-75% in the stem and bark, 15-20

% in coarse roots, 5-10 % in the crown (branches and foliage). Biomass

in stem and bark on a 40 year old Douglas fir stand on a high productivity

site was about 76 % (Cooper 1983), and this proportion was about

73 % in a low productivity site planted with Douglas-fir (Keyes

& Grier 1981). Similar values have been established for old

growth Douglas-fir in western Oregon (Grier and Logan 1977).

Looking at the components on conifer stands separately, a nearly

complete foliage cover is established early in stand development

of most forests and remains essentially constant until maturity

(Grier & Logan 1977, Keyes 1979, Cooper 1983). Branches, as

extensions of the stem, can accumulate carbon through the life of

the tree. The fraction of biomass in branches is usually higher

for hardwood stands, with as much as 25 % of the biomass found in

that component. This proportion is much smaller for conifer trees,

with about 5-7 %. The stem biomass increases rapidly with age while

the foliage biomass stays fairly constant (Grier and Logan 1977).

Carbon content is approximately 50 % of the oven dry weight (Reichle

et al 1973, Harmon et al 1990) with slight differences related to

the chemical and physical composition of some of the components

(Vogt 1991).

2.1.3 Below ground living biomass

The importance of roots as structural, storage and physiological

organs has been acknowledged for quite some time (Harris 1971, Santantonio

1977). However, they have not been, for the most part, included

in ecosystem research because of the difficulties surrounding their

study. Observations are not possible without major disturbances

in the soil, while changing dramatically the environment of the

roots.

The development and buildup of the roots biomass is more complex

than some of the above ground components. This is due to the variety

of roles played by coarse and fine roots: structural support, food

storage and nutrient absorption for example. However, in their 1992

study on spatial disposition and extension of the structural coarse

root system of Douglas-fir, Kuiper & Coutts found significant

positive correlations between all the coarse root parameters studied

and the tree diameter at breast height (dbh). Furthermore, data

on the relationship between coarse root biomass and dbh in Douglas-fir

in the Netherlands was found to be consistent with natural stands

of Douglas-fir in the Pacific Northwest (Santantonio et al. 1977),

even though the site conditions and management history between the

two sites were very different. Dbh, which is readily available,

has therefore been shown to provide good estimates for woody root

biomass.

Decomposition rates for woody roots in forest ecosystems of the

Pacific Northwest were estimated by Chen et al. (2001), with Douglas-fir

roots having an estimated decomposition rate of 0.05/year for roots

between 4 and 12 cm.

Fine roots on the other hand are very hard to account and simulate

based on growth models. An extensive study on fine root biomass

related to stand age and productivity found no significant differences

among stands of different age but same site productivity (Vogt et

al 1987). Another study did a sensitivity analysis dealing with

the incorporation of fine roots biomass into the soil carbon, leading

to the assumption of fine roots flux being relatively constant (Cropper

and Ewel 1984). In biomass studies and budget estimations, fine

roots biomass estimates from previous studies are added to the total

estimated by the simulations (Harmon et al 1990, Keyes & Grier

1981), or total root biomass is based on a percentage of the bole

(Bruschel 1993), but none of the studies from the literature reviewed

provided a potential way of simulating their growth and death.

2.1.4 Forest floor

Carbon accumulation in detritus and soil often accounted for greater quantities of biomass than the living biomass, especially on hardwood stands (Schlesinger 1977, Covington 1981, Gholz & Fisher 1982, Moore & Braswell 1994). The return of organic litter to the forest floor is complex and very variable. Factors to consider among others are: the age of the stand, the species composition, the density of stand, the site productivity and the environmental conditions (Bray & Gorham 1964). It is clear that litter-fall plays a fundamental role in soil formation and site productivity (Bray & Gorham 1964, Schlesinger 1977, Covington 1981, Gholz & Fisher 1982, Moore & Braswell 1994). It is also clear that both the carbon chemistry and nutrient concentrations of litter strongly affect its decomposition (Aber et. al. 1990). Thus, detrital mass changes more rapidly than soil carbon with disturbances.

The amount of change when harvest occurs will be highly dependent upon the harvesting method, the stand composition and the climatic conditions (Cooper 1983). Harvesting usually increases decomposition rates of the detritus material because it causes higher soil temperatures and moisture, together with increased availability of inorganic nutrients needed by decomposers (Aber et al 1978). Temperature and moisture variables have been found to be the main factors explaining decomposition patterns, stronger when considering them together rather than individually (Gholtz et al 2000). Turner and Long (1975) showed that leaf litter (which has the highest concentrations of nutrients and decomposes faster) decreases in time, but total tree litter increases in time because of returns of less decomposable woody litter. Similar results were found in old growth Douglas-fir ecosystems, where woody material represented about 60% of the biomass returns (Grier et al 1974). A study on Douglas-fir stands ranging from ages 22 to 160 showed that a typical leaf litter production is 2 MT/ ha/ year, while total litter is in the ranges of 2.5 MT/ ha/ yr (Gessel & Turner 1976). Annual fall of litter increases until about age 40, and then becomes relatively constant while total litter continues to increase because of woody litter, although it can be very irregular.Dimock (1958) showed what intuitively seems correct with regards to thinning operations: decreasing levels of litter fall with increasing intensity of thinning regimes on Douglas-fir stands.

The decomposition of coarse woody debris although little understood, is a very important aspect of nutrient cycling in forest ecosystems of the Pacific Northwest (Harmon 1992). Turner and Long (1975) calculated decomposition rates for an age sequence of Douglas-fir stands. The decomposition rate starts at about 0.05 /year for a young stand, and increases to about 0.16 /year at age 30, decreasing to about .1 /year at age 50 and above.

2.1.4.2. Logging debris: slash

Slash burns are very rarely done anymore and have not been done

for most of the last 20 years because of smoke. On the west side

of Washington Cascades, on slide ground, the slash is left unburned

unless whole tree yarding is the harvest method. In the case of

whole tree yarding, logs are processed by a delimber and slash is

burned on the landing. On gentler terrain, where the cut-to-length

system is used for thinning, slash remains unburned. When shovel

logging is the harvest technique for a clearcut, burn piles are

created and combustion is fairly complete (Mason, personal interview,

11.2001).

Harvesting can have a significant increase or decrease effect on

forest floor biomass, mostly based on how much slash is left behind

after the operation (Johnson 1992).

2.2 Managing for carbon sequestration: the Silviculture

2.2.1 Longer rotations

Long rotations develop structurally complex managed forests and increase the accumulated timber volume per unit area (Franklin et al 1997, Burschel et al 1993). Longer rotations are ecologically viable because Douglas-fir (Pseudotsuga heterophylla) and other associated conifers can live to a very old age and their productivity is maintained to advanced ages (Curtis 1997). Longer rotations should be combined with thinning regimes to increase the productivity and the size of trees in a shorter time span. Larger trees imply higher wood quality, and the thinning regimes can provide revenue as intermediate operations. Longer rotations allow for adjusting unbalanced age distributions, increasing the quality of wildlife habitat associated with late successional forests, and increasing the net standing carbon storage capacity.

2.2.2 Variable retention

The variable retention system (Franklin et al 1997) is based on

the concept of retaining structural components of a particular stand

for at least another rotation. The development and maintenance of

a structurally complex forest is the most important point when talking

about the restoration of a forest. It is very flexible and the level

of retention directly relates to the management objectives. It is

important to consider other functions of these structural components,

beyond the carbon sequestration per se, such as the enriching attributes

and enhancement of connectivity throughout the landscape. The idea

is to provide structural elements for diverse habitat requirements,

ameliorate the microclimatic conditions, and maintain microfauna

(mycorrhizal fungi, lichens etc). Enriching stand structure by maintaining

living and dead structural material of various sizes, species, and

levels of decay through aggregated or dispersed retention can also

be incorporated into the management of the forest. Leaving behind

coarse-woody debris following thinning and harvesting operations

is recommended to increase the carbon in the forest floor.

The management objectives will determine what will be retained,

how much and in what pattern. Large trees with special features

such as rot pockets, cavities and large limbs or clusters of limbs

should be retained. Snags in different states of decay and sizes,

as well as coarse woody debris in different sizes and stages of

decay should also be retained. The pattern in which these structures

are to be left will depend on the stand and its characteristics.

Aggregated retention will be preferred at some points, and dispersed

retention will be the choice on others, hopefully through the mixture

achieving greater complexity and carbon sequestration. Shelterwood

(Smith et al 1996) for example, is a type of dispersed retention

of dominant and co dominant wind firm and stress tolerant trees,

that will provide in time a well distributed source of snags and

coarse woody debris.

2.2.3. Thinning regimes

Thinning can be used to promote the overall health of a forest,

through reduction of high fuel loads and increased wind stability.

Thinning can be used to salvage material from disturbances and avoid

insect outbreaks (Smith et al 1996, Oliver & Larson 1996). This

is an important consideration when addressing issues such as fire

safety, insects, wind stability and diseases. More important however,

thinning can be used to accelerate the stand dynamics of a particular

stand, favoring certain structural components that have a functional

value, releasing growing space for understory species and advanced

regeneration, or simply to increase the size of trees. Thinning

in restoration is used as a tool that affects the structure of the

stand. Pre-commercial thinning (PCT) is applied near the end of

the stand initiation to enhance survival, growth and value of the

residual trees. It increases stand uniformity but promotes tree

growth and understory development (shrub and herbaceous) allowing

also for early establishment of shade tolerant species (Oliver and

Larson 1996). By doing a PCT, the differentiation of the stand is

accelerated and the structural and species components increased.

The spacing can vary in patches through the plantation, with small

openings or gaps created to retain components of the early initial

stage.

Thinning combined with extended rotations can maintain forest cover

for long periods while still providing wood products, through allowable

intermediate operations; timber flow can be sustained during intermediate

stages of development with the benefit of ecological processes being

maintained and higher wood quality achieved (Oliver 1993, Burschel

et al 1993).

2.3 Accounting for the sequestered carbon

The Kyoto Protocol to the United Nations Framework Convention

on Climate Change (1998) prescribes that net flows into or out of

the biosphere will be represented by the changes in carbon stocks.

This notion simplifies the measurements and accounting processes.

The Intergovernmental Panel on Climate Change (2000) is consistent

with this prescription, defining carbon sequestration as an increase

in carbon stocks anywhere but in the atmosphere. The important issue

is "additionality" (Chomitz 2000). Additionality addresses

the idea that carbon sequestration or reduced emissions can result

from a management change. Management alternatives can be compared

against a base line, to measure the change from "business as

usual". Afforestation of grazing land for example, is a one

time huge addition of carbon pools and if reforested after disturbance,

the carbon pools can be maintained through a long period of time.

How do we measure carbon and how can we estimate the variations

in the different terrestrial pools? Biomass is one of the key characteristics

of forest ecosystems because it contributes in the definition of

carbon flux and nutrients, as well as the potential standing and

dead organic matter in a particular site. Biomass studies are essential

for understanding ecosystem dynamics. Biomass studies are static

however, describing and estimating living and dead material in a

particular stand at a particular time (Santantonio et al 1977).

Combining biomass studies with growth models seems to be the most

straightforward manner for estimating component masses at different

points in time at the stand scale. The carbon storage pattern simulated

by the model is static, meaning productivity of site is assumed

constant as embedded in the original inventory in question, without

possible changes associated to different temporal scales, like the

global warming issue. The Kyoto Protocol specifies integration of

greenhouse emissions with corresponding offsets credits if carbon

is removed from the atmosphere on a 5-year commitment period. Integration

over spatial scale might be used as well to decrease the costs in

accounting, monitoring and verification.

2.4 Forest products, biofuel and substitution

Harvesting of forest ecosystems changes the natural carbon cycle

between the terrestrial pools and the atmosphere. Therefore, the

balance between forests and forest products is an important component

in any budget analysis and should be included.

The carbon fluxes related to the harvesting activities should follow

the general equation for atmospheric flow (Winjum et al 1998): net

carbon flux to the atmosphere = carbon fluxes to the atmosphere

from harvesting activities and forest products - carbon sequestration

during development of the forest. The carbon fluxes associated with

forest harvesting activities and the use of wood should include

the carbon emissions from decomposition of slash left in the forest

after harvest, the burning of fuelwood, the waste from manufacturing

wood products, and the decay of the products pool.

Over a long term period, the amount of carbon stored in the biosphere

reaches a steady state, and continuing mitigation of carbon emissions

depends on the degree fossil fuel use is displaced by biofuel and

wood products (Schlamadinger & Marland 1996).

A modeling study comparing the growing of trees to sequester carbon vs. growing trees to substitute fossil fuels showed that many factors influence this trade off. Important variables were: forest productivity, the efficiency of the production of wood based energy, previous land uses and the time scale considered (Marland & Marland 1992). The benefits in terms of using wood as energy instead of leaving it in terrestrial pools of storage increased with increased productivity of the site, with greater time intervals considered and with the efficiency and usage given to the biomass products.

There is also the idea that forest products require less energy in their manufacture than other products for the same use. If wood products can replace more energy intensive products with the same function, the substitution by wood products will also provide a decrease in the carbon emissions to the atmosphere (Koch 1991). Aluminum, steel, cement, bricks and synthetic materials derived from fossil fuels cause a greater energy consumption and greater carbon additions to the atmosphere. For example, the net energy required per ton of lumber studs is 2.91 million BTU (oil equivalent). The net energy required per ton of steel studs is 26.67 million BTU (Koch 2001).

The Intergovernmental Panel on Climate Change (1990) recommendations and guidance with regards to response strategies in the forest management context included the replacement of fossil energy sources by sustainably managed sources of biomass, increase substitution efforts of highly energy consuming products by wood, technology improvement with regards to the use of fuel wood, and encouragement of the recycling of forest products to provide even longer storage for carbon pools.

2.5 Carbon credits

The Kyoto Protocol to the United Nations Framework Convention on

Climate Change (1998) has proposed a way for establishing limits

on greenhouse gas emissions to be enforced internationally, with

different types of commitments for developed and developing countries.

The protocol allows, within a set of rules, for countries to use

their terrestrial sinks to offset part of their greenhouse gas emissions

from other sources.

The idea of emission trading has also been included in the Kyoto

protocol. Countries listed in Annex B of the protocol can offset

their own emission reduction commitments by engaging in emission

reduction activities in another Annex B country (developed) or a

non Annex B country (developing). The protocol is however unclear

if carbon sequestration can be used the same way the emission reductions

activities are carried between Annex and non Annex B countries.

Among other issues to be resolved before the Kyoto protocol can

be implemented internationally and commitments enforced internationally,

is that accounting rules for emissions and reductions need to be

tested and put in place (Marland et al 2001).

Birdsey and Heath (1997) estimated on a large scale assessment that over the past 40 years, US forests have sequestered enough carbon to offset approximately 25 % of the current US emissions. Creating a market for reducing carbon dioxide emissions through forest sequestration requires three elements: a market framework, demand from willing buyers and supply from willing sellers. For a market framework to be successful, it requires a policy and political framework. Willing buyers come from consumers interested in reducing their emissions. They need insight about the options that forest conservation and management provide in terms of reductions and mitigation. The third part has to be about providing the supply: landowners understanding the carbon dynamics of their forest, how to increase it through management and how to access the markets.

One last point: trying to protect the global climate through carbon sequestration, by coming up with efficient accounting mechanisms that encourage carbon sequestration in forests and forest soils also provide incentives for other desired activities such as the sustainable management of natural resources and protection of biodiversity.

3. METHODS

A prototype carbon sequestration analysis model was developed for the West Cascades of the Pacific Northwest region. It is to be used with tree list inventory data and growth and yield model simulations of inventory conditions. Microsoft Excel was selected for use as the spreadsheet program with which to build the carbon storage model. The model was designed to be easily adapted and updated. Certain carbon factors can be very specific to a particular area and new knowledge is constantly being acquired on the carbon cycle and its components and should be considered if pertinent. Due to the complexity of the carbon cycle and to the accuracy of the carbon model created, carbon storage evaluations are done at the stand level (Apps & Price 1996; Harmon 2001). The complexity of carbon accounting, and the success estimating a carbon balance for the system, increases with the increase of the spatial and temporal scales: the more complex the hierarchy of the system, from individual tree to the landscape level, the more complex its representation and estimation.The carbon model is an attempt to develop a closed carbon model in which all flows into and out of the system are mathematically accounted for. It is at the input and output level where simplifications were made so that forest carbon balance questions could be defined. It is assumed the forest occupies an area of uniform site quality. Also, that changing climatic conditions and CO2 concentrations do not affect processes and their rates, and that repeated harvesting does not reduce long term site productivity.

There are two main parts in the carbon model: the forest module and the product module. The displacement and substitution analysis are derived from the products module.

A critical aspect of the model is that it has to be functional and applicable to a wide array of forest management scenarios and stand conditions. For the forest module part of the model, which is the base of the carbon model, the data required is taken from the Landscape Management System (LMS ) (McCarter et al 1998). LMS is an evolving software application developed at the University of Washington- College Of Forest Resources- Silviculture Laboratory. LMS is designed to assist in landscape level analysis and planning of forest management alternatives. It is implemented as a Microsoft Windows (TM) application that coordinates the activities of other programs (projection models, visualization tools, etc.) that makeup the overall system. Since LMS is modularly designed, it can accept many growth model alternatives for use with simulations.

LMS was utilized to perform projections of inventory conditions providing a broad spatial and temporal context for carbon storage evaluation at the tree and stand levels over a variety of growth and treatment periods. For the PNW forest simulations, the PNW variant of the Forest Vegetation Simulator (FVS ) (Wykoff et al 1982) was selected as the growth model for use within LMS. FVS is a distance independent growth and yield model based on individual tree records. These tree records (diameter, height crown ratio, TPA, etc.) will define growth for small and large trees, as well as mortality, which is density dependent. FVS allows modification of the response of the growth model, making it possible to adjust for specific stand conditions. The PNW variant applies to 37 species from the region. It can portray single or mixed species, even and uneven aged, on a wide variety of forest types. The simulations and analysis are concentrated on conifers and specifically within the Pseudotsuga menziesii and Tsuga heterophylla (Franklin and Dyrness, 1973) forest types.

3.1 The Forest carbon

The carbon forest module includes the following components: branches

(dead and live), foliage, stem and bark, standing dead trees (snags),

coarse roots and litter (harvest slash, dead branches and foliage).

Forests are considered a standing pool of carbon at any point in

time.

The forest module of the carbon model is based on accounting for

all allocations through biomass estimates at discrete points in

time, which establishes where and how much is sequestered in what

components. This allocation changes in time through losses by decomposition,

and harvest operations that use fossil fuels.

Carbon additions or reductions to atmospheric pools resulted from

forest growth, silvicultural treatments and decomposition. These

additions (sequestration) and reductions (emissions) were calculated

as the difference between total estimated forest carbon storage

the growth period before treatment and total estimated forest carbon

storage for the growth period post treatment (Figure 2).

|

| Figure 2. Forest module based on carbon sequestration (additions) and carbon emissions (reductions). |

Soil carbon changes were ignored due to the complexity

of assessing carbon budgets through time after silvicultural operations,

and from the leaching of organic and inorganic carbon at that level

(Harmon et. al. 1990). Research attention has been given to below

ground processes, respiration and foliage dynamics (Landsberg et.

al. 1991), and as information becomes pertinent should be integrated

to the system.

The model has been developed for 5 year growth periods, but LMS

allows for an increase of this time for operations assessed with

10-year growth periods, in which case equations would account for

this change.

The first step is to convert the LMS scenario tables for the forest,

the cut and the snag inventory from English to metric units to be

consistent with the units required for the regression equations

used. The scenario table shows individual tree records with its

respective attributes for all the management periods considered.

Regression equations developed by Ghotlz et al (1979) were used

to estimate tree component dry weight biomass based on diameter

at breast height (d.b.h.) for branches, foliage, stem, bark, snags

and coarse roots in kg/ ha. High correlations are usually found

in logarithmic regressions of dry weight on d.b.h. According to

Bunce (1968), this is in part due to the balance between apical

and radial growth, and because logarithmic units represent progressive

orders of magnitude. The estimation of current and total foliage

biomass using d.b.h. has been shown to have errors in the regression,

especially in older stands, and this should be taken into account

(Grier & Waring 1974, Snell & Brown 1978, Marshall &

Waring 1986). All results however, are benchmarked against biomass

estimates found in the literature (Grier & Logan 1977, Keyes

1979, Edmonds 1980, Vogt et. al. 1980, Gholtz 1982, Cooper 1983,

Keyes & Grier 1981, Santantonio & Herman 1985, Vogt et.

al. 1986, Edmonds 1987, Vogt 1991). The equations, unless cited

otherwise, follow the form:

(1) ln Y = a + b ln X,

where a and b are regression coefficients, Y is the dependent variable and X is the independent one. The equations are species and component specific and have been used in several biomass studies in the region to determine dry matter production (Grier and Logan 1977, Gholz 1982, Cropper and Ewel 1984, Vogt et al 1987, Harmon et al 1990, Canary et al 1996). Derived from equation (1), the equations for biomass (B) follow one of the three forms, depending upon species and component (Appendix A):

(2) B = e b0 * dbh b1

(3) B = b0 + b1 * dbh 2 * ht/100 - b2 * (dbh 2 * ht/100) 2

(4) B = b0 + b1 * (dbh 2 * ht/100)

where b0, b1 and b2 are regression coefficients that are species and component specific (Ghotlz et al. 1979). Standing carbon was estimated by multiplying the biomass output by a proportion factor that depends on the species and component, but averages 50% of dry weight (Reichle et al 1973, Harmon et al 1990, Birdsay 1992). The carbon output is then summarized into three groups: stem (bark and trunk), crown (foliage and branches) and soil (coarse roots). The understory carbon pool represents approximately 1% of forest carbon (Turner at al 1995). Since this is a small percentage of the total forest carbon pool and because models are not available to link understory biomass to tree inventories, estimations of understory carbon storage were not included in this project.

The woody debris pool consists of snags, dead coarse roots and litter fall. The largest pool of organic carbon in most forest stands is soil organic matter and detritus (Schlesinger 1977). Litter mass changes more rapidly than soil organic matter. For the purpose of this project no loss of soil carbon was assumed due to harvest as indicated by three major studies (R. Boone et al 1988, Harmon et al. 1990, Johnson 1992). It is also assumed that the carbon flux of fine roots is balanced: fine roots grow and die at the same rate (Santantonio et al. 1977, Cropper & Ewel 1984). Therefore, organic soil carbon was determined to be relatively constant and was not included in the overall equation for carbon pools.Litter fall was defined as a variable percentage of the total foliage and branches biomass, with an average of 10% of the foliage and dead branches total biomass assumed to accumulate in the litter pool for the 5-year growth period (Franklin and Spies 1988, Edmonds 1979, Grier and Logan 1977). The litter fall pool increases after each treatment because foliage and branches are assumed to be left scattered on site. This means that on the west side on steeper slopes the slash is left unburned unless whole tree yarding is the harvest method. On the gentler terrain where the cut-to-length system is used for thinning, slash remains unburned. Again, for simulation purposes, foliage and branches are considered to decompose on site instead of being burned.

Root biomass of harvested trees was also accounted for and decomposed through time, adding this biomass to the live root biomass pool.

Snags were determined by the tree mortality predicted by the FVS growth model. The general equation for calculating snag biomass (SB) uses species specific equations for live trees corrected for density (Canary et al 1996):

(5) SB = (biomass of live tree stem (Gholtz et. al. 1979) * density of snag (Spies

1988)) / density of live tree (Hartman et al. 1976)

The snag carbon content was estimated by multiplying the snag biomass

times the species carbon factor, which is very close to the live

tree carbon factor. The change in carbon content with regards to

the biomass of the component remains relatively constant between

live and dead trees (Sollins et al 1987). Existing stumps were not

considered in the carbon pool, because data on those components

was not available for calculation.

The reduction of the different biomass pools, such as snags, litter

fall and coarse roots were estimated by decomposing them according

to species specific annual decomposition rates developed by Harmon

(1993)(Appendix A) based on the literature (Harmon et. al. 1986).

They have been evaluated and used by major studies (Turner et al

1995, Birdsay 1996). Estimation of subsequent reductions of carbon

from the decomposing components from the forest module were calculated

using the following equation:

(6) Xt = X0 (1- k * t ) ,

where Xt is the carbon biomass at time t, X0

is the initial biomass, k is the species specific constant

describing the biomass loss per year and t is time in years (Aber

and Melillo 1991). The mass of decomposing material is the sum of

mortality in the most recent interval (5 year periods) and the residual

mass of decomposing material (Xt).

Because LMS projections work on 5 year steps, the equation generally

used within the model follows the form:

Total Xt1 = Xt 0->1 + ((1-k)5 * Xt0),

where Total Xt1 is the cumulative carbon in a certain component at time t1, Xt 0->1 is the carbon accumulated in that component in the period t0 to t1, k is the decomposition rate, 5 is the number of years and Xt0 is the carbon found in that component at time t0.

3.2 The Carbon in Products

Carbon sequestration goes beyond what can be measured in the forest

as live and standing or dead and decomposing. Forest products constitute

a very important pool for capturing carbon on a long-term basis,

especially when emphasizing the use of wood on long term products,

such as lumber for structural components in residential construction.

Products are modeled with a constant rate of products loss to the

atmosphere, as most studies that have addressed products have done

(Houghton et al. 1983, Harmon et al 1990, Oliver at al 1990, Dewar

1991, Harmon et al. 1996). The model does not allow for changes

in time in terms of technological improvements in manufacturing

efficiencies and product use, and does not include disposal since

it includes continuous decomposition. The model considers the raw

biomass harvested, its conversion to products through manufacturing,

and the accumulation and decomposition of the product pool through

time.

The products module takes all the biomass harvested at different

points in time, allocating part of it to long term and part to short

term carbon pools. The long term products constitute the base for

the substitution assessment. The short term products are the base

for the displacement of fossil fuels by biofuels. Harvesting and

manufacturing emissions are also part of the carbon model accounting

(Figure 3).

|

| Figure 3. The products module and its components within the carbon model. |

Starting with the Volume summary table from LMS,

with forest and cut volumes for a particular scenario, the amount

of forest products is determined by using a set of studies recently

conducted in the Pacific Northwest by C.O.R.R.I.M. (2002). Four

mills were surveyed in the region, producing dimension lumber as

their primary output. The manufacturing process was divided in four

units: sawing, drying, planing and energy generation. The numbers,

coefficients and factors used in this part of the carbon model are

the average values derived by weighting the production at each one

of these mills (Appendix B).

The spreadsheet starts with total raw volumes of harvested material

per stand given in ft3/acre. Using an average lumber

yield of 9.9 bf/ ft3, volumes in ft3 are converted

to Mbf (thousand board feet) of dry planed lumber. In order to produce

one Mbf of dry planed lumber, 101.01 ft3 of raw logs

are required. This standard yield is neither species nor diameter

sensitive. The four mills reported a range from 90.4 to 105 ft3

of logs /Mbf of lumber. A wood density of 28.08 lbs/ft3

was used for Douglas-fir and 26.21-lbs/ ft3 for western

hemlock (US Forest Products Laboratory, 1999) to convert volumes

to mass.

Co-products from the sawing unit are added to the ones from the

planning unit to give co-product totals for the manufacturing process.

These totals are used as average biomass outputs for co products

based on the volume units (Table 1). The outputs from this part

of the products module are Mbf /volume harvested, the biomass of

dry planed lumber obtained from this volume, an the biomass of co-products,

in English and metric units.

The volume conversion numbers can be modified according to specific

cases, for example, when greater or less efficiencies at the mills

can be accounted for. These conversion numbers were taken from the

average of the operations and efficiencies for the mills surveyed

in the PNW region. They combine an 86% recovery at the planer, with

56% recovery at the sawmill, giving an overall yield of approximately

48% for planed dry lumber from raw logs. At this level of the analysis,

100% of the harvested material was considered lumber yield material,

with no differentiation towards plywood material.

The products carbon content is assumed to be approximately 50% of

the dry weight biomass (Birdsay 1996, Winjum et al 1996). Co-products

are green and hog fuel is assumed to be at 50% wet base moisture

content, a value given by the mills.

The carbon pools of lumber and co products were estimated to decompose

according to species-specific annual decomposition rates (Harmon

et al 1996, Winjum et al 1996). Estimation of carbon loss to the

atmosphere through decomposition were calculated using equation

(6) with specific constants describing the decomposition of long

and short term storage products. The total products carbon at time

1, Xt1, is the sum of products harvested and manufactured

in t0 decomposed for the 5 year interval between t0 and

t1, plus the products harvested and manufactured in t1.

This calculation works for long term and short term storage products,

and the decomposition of these two products pool is calculated separately

within the products module of the carbon model.

3.2.1 Carbon Emissions

Carbon emissions from forest operations are based on the amount of fertilizer, lubricant and fuel consumed in the intermediate operations (pre commercial and commercial thinning, fertilization) and final operations (harvesting). Emissions from regeneration activities are not accounted for because they are not significant (Johnson personal communication. 3/2002). The amount of fuel and diesel consumption depends on the harvesting equipment, the amount of fertilizers applied at the seedling stage and as intermediate operations, the intensity of silvicultural treatments, and the distance to the mills for processing of the logs. Carbon emissions are estimated and defined based on outputs from the SimaPro model (Franklin Assoc. 1998) and Johnson's harvest factors (personal communication, 3/2002) and will be explained later in this part of the chapter.

Diesel consumed is estimated to be 0.0184 gallons/ ft3

of timber volume extracted for the regeneration harvests, and 0.0246

gallons /ft3 of timber volume extracted from the thinning

operations (Keegan et al. 1995). The lubricant consumption is assumed

to be 1.8% of the fuel consumption (Kellog at al. 1996). Diesel

for hauling corresponds to 0.0276 gallons/ ft3 of timber

volume transported (0.0006 gallons/mile of transport). Hauling production

and fuel consumption include empty and loaded travels over the specified

distance. This distance can be changed according to the reality

of the projection. For the case studies the distance is assumed

to be 35 miles one way.

By using conversion factors of 138,881 British Thermal Units (BTU)/

gal for diesel and 148,832 BTU/ gal for lubricants (Johnson 2002),

the amount of BTU/ acre from the use of these two products can be

determined for the amount of volume harvested on the acre and hauled

from the simulated stands at any particular point in time. From

this, the amount of BTU/ft3 can be determined as well.

The harvesting and regeneration emission factors from the SimaPro

model are given in kg of compound emissions/ MegaJoule (MJ) (Table

2).

| Table 2. Emission factors from the SimaPro model. (Franklin Assoc. 1998). | ||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||

Joule is the metric unit for energy. The amount of diesel and lubricant in BTU/ft3 must be converted into metric units. For this, the volume from each silvicultural operation in ft3/ acre is multiplied by 0.7 to obtain m3/ha. With volume and area in metrics, MJ/m3 can be determined. The output in MJ/m3 is multiplied by the SimaPro emission factors (kg/MJ) to obtain emission outputs in unit weight/ unit volume harvested in metric units and are converted to English units (kg/ m3 and from that to lbs/ ft3 ). Emission compounds addressed by this part of the module are: carbon monoxide (CO), fossil carbon dioxide (CO2) and non-fossil carbon dioxide (Franklin Assoc. 1998). Fossil carbon dioxide represents the emissions from fossil fuels, and the non-fossil carbon dioxide comes from the burning of biomass in a wood boiler.

The emission numbers are presented in terms of total carbon emissions in kg/ha and lbs/acre for the volume harvested every time a treatment is performed. The amount of carbon emissions is determined by multiplying the total emissions by the atomic weight of carbon and dividing by the atomic weight of the compounds in question (CO: 12/28 and CO2 : 12/44). Carbon emissions from forest operations are cumulative through time because less than 2 % of the emissions come from non fossil sources.

The amount of fertilizer for regeneration is estimated at 0.0009 lbs of nitrogen, 0.00016 lbs of phosphate and 0.00039 lbs of potassium/ seedling (Schlosser et al, 2001). The intermediate fertilization is assumed around age 30, with 465 kg of urea/ ha (413 lbs of urea/acre) which should leave about 225 kg/ ha (200 lbs/acre) of nitrogen in the ground. Fertilization emissions are based on an average rate of 50 ha/ hour (120 acres/hour) for the amount of fertilizer assumed (Webster, personal interview 11/2002). Using average density of 12.97 barrels per metric ton for liquid petroleum gas (LPG), and 42 gallons per barrel, the weigh of LPG is 1.8 kg/ gallon. With an 80 % of weight in carbon, and 1.67 gallons of LPG/acre required for the running of an average size helicopter used in these types of fertilizations (Johnson 2002), the emissions are estimated to be about 6 kg /ha (5.3 lbs/acre), an almost insignificant addition, nevertheless accounted for in the process.

3.2.1.2 Manufacturing emissions

Manufacturing emissions from the production of one Mbf of planed dry lumber were exported from the CORRIM database (CORRIM 2002 unpubl.) determined by using the SimaPro model (Franklin Assoc. 1998) (Table 3). The Life Cycle Assessment protocol established that manufacturing emissions are to be accounted as burdened emissions. This means the manufacturing emissions shown in Table 3 are only 56% of the sawing emissions and 86 % of the planning emissions, with the co-products burdened with the remain emissions.

| Table 3. Air emissions from production of one MBF dry planed lumber | ||||||||||

|

Unit factors for the carbon emissions were established for the manufacturing process considering a mix of Douglas- fir and western hemlock in the production of dry planed lumber. The ratio of the mix between the two species is not considered to affect the overall air emissions, since the two species are very similar. These unit factors for CO, CO2 fossil and non-fossil, and CH4 are multiplied by the number of Mbf produced from the harvested volumes and summarized in terms of kg/ha and lbs/acre of carbon emissions. Drying emissions are assumed to be 0.009 kg carbon /Mbf (0.2 lb carbon/MBF) as reported by the mills and are part of the overall manufacturing emissions output. Manufacturing emissions are further summarized in metric tons/ha and thousand lbs/acre and are cumulative through time.

All manufacturing emissions in this phase of the model are considered to accumulate through time because the majority of the emissions are fossil emissions. However, this fossil fuel usage is a reflection of the mills surveyed, and not necessarily the reality of the region. In fact, more than 50% of the energy for lumber production comes from biofuel usage according to data gathered recently. This information on the biofuel usage was just recently updated (Wilson, personal communication, 10/2002) and further adjustments within the products module need to be done to better differentiate between fossil and non fossil emissions, the emissions from non-renewable and renewable resources.

| Table 4. Updated air emissions from production of one MBF dry planed lumber. | ||||||||||

|

3.2.2 Displacement of Fossil Fuels by

wood

The amount of carbon stored in the biosphere reaches

a steady state, and continuing mitigation of carbon emissions will

depend on the extent to which fossil fuel use is displaced by biofuel

(wood energy) and the level of wood products usage.

As long as the wood used for fuel in the wood boiler is replaced

by new growth, there is no net increase in the amount of CO2

released. The carbon in the fossil fuel not used, having being displaced

by the usage of wood, remains in storage. This storage is cumulative

through time since the displacement of fossil fuel is permanent

(Burschel et al 1993). Manufacturing emissions are burdened for

the use of the co-products as source of energy with 100% of the

emissions from the manufacturing of lumber together with the co-products

outputs.

These factors, together with numbers taken from the Energy Information Agency (2001) on average carbon emissions from different fossil fuels are the basis for the displacement calculations. The share of co-products that are used for their fuel value varies widely depending upon their price relative to alternative energy sources. Maximum displacement at harvest uses all of the co-products (bark, chips, shavings, sawdust and fuel bark) as biomass for energy (i.e. fuel for the wood boiler). This biomass permanently displaces the fossil fuels that would have been burned to produce the same amount of energy.

With an average of 75% carbon per unit weight, 0.0145 metric tones of carbon are released for every million BTU produced with a natural gas boiler (1000 ft3 = .816 million BTU). With an average of 80% carbon per unit weight, 0.01716 metric tons of carbon are released for every million BTU produced with a diesel boiler.

For the case studies evaluated in the applications of the carbon model, natural gas boiler was evaluated against a wood boiler; therefore the displacement equation follows the form:

Displaced carbon in Metric tons/ha = BTU produced with hog fuel/ ha * 0.0145.

3.2.3. Substitution: wood vs. steel in construction

When managing a fix number of hectares while producing

more or less products through different management scenarios, substitution

by other more energy intensive products will occur when wood products

are not available from the fixed land base.

The substitution analysis assesses the contribution of a single

hectare to the already existing mix of wood and steel framed houses

for a certain region. The region, in this context the Minneapolis

region, has a market in which about 100,000 new houses are build

every year, with 80,000 wood framed dominant and 20,000 steel dominant.

The assumption is that adding one wood house to this matrix results

in the subtraction of one steel house, so that all measurements

are consistent with a fixed unit of consumption, in this case a

fixed number of house units providing equivalent service.

Starting from a base case scenario with a defined wood flow through

time (in this case the 40 Base Rotation), the wood for about 4 wood

framed houses out of the total market comes from our hectare at

harvest. The contribution coming from any change in the management

of our hectare to the change of that mix of wood vs. steel framed

houses is what is being considered by the substitution analysis.

When more wood is produced, less carbon will be emitted per hectare

because less steel will be needed and less fossil fuel will be used.

More carbon is emitted per hectare when wood is not available on

our hectare because steel, a higher energy manufacturing product,

has to be used instead of wood.

The total wood biomass required for a wood framed house is roughly double the wood biomass required in the steel framed design. The biomass harvested, in metric tons/ ha of wood at different periods in time, is the base for the assumption that wood design construction is applied when wood is harvested on the hectare and steel design construction is applied when wood is not harvested on the hectare.

There are two equations used in the calculations for substitution:

1. X t1 (total wood harvested at time t1) = 14.37 Hw + 7.74 Hs

H = number of houses, w = wood, s = steel ,

where the coefficients represent the wood mass in each house (14.37 metric tons for the wood framed house and 7.74 metric tons for the steel framed house).

2. Hw + Hs = 1

Solving two equations for two unknowns, the number of potential wood framed and steel framed houses is determined based on the amount of wood fiber harvested at a particular point in time:

Xt1 (total wood harvested at time t1) = 14.37 Hw + 7.74 (1-Hw)

Xt1 = 6.63 Hw + 7.74 => Hw = (Xt1- 7.74)/ 6.63

=> Hs = (Xt1- 14.37*Hw)/ 7.74

When no wood is harvested in our hectare, Xt = 0 and the calculation establishes that the regional matrix of houses will have 1.17 less wood framed houses and 2.17 more steel framed houses than the base case. Fractional units simply indicate the contribution share for our one hectare example.

The Global Warming Potential (GWP) index (CORRIM 2002, app G) was used for the calculation of the tradeoff in terms of carbon emissions of the construction of a wood framed house versus a steel framed house. The estimates of carbon emissions for both house designs have been calculated from the resource extraction to the construction of the buildings, with all steps in both processes accounted for. The number of houses, Hw and Hs at a particular point in time, are then multiplied by their respective GWP Index to determine the amount of CO2 sequestered and emitted by such constructions. The GWP Index is the impact assessment in terms of CO2 released to the atmosphere, together with the equivalent of other gases with global warming effects. The equation is as follows (EMR Canada 1990):

GWP index (kg) = CO2 (kg) + [3 CO(g) + 150 Nox(g) + 63 CH4 (g)]/1000

The GWP index is 39,810 equivalent CO2 kg for the wood framed house, and 59,290 equivalent CO2 kg for the steel framed house. These numbers are the base for the CO2 emission substitution equation that has the following form:

CO2 tradeoff equivalence = - Hw * 39,810 + Hs * 59,290.

This number is later converted to carbon emissions

by multiplying it by the atomic weight of carbon with regards to

the CO2 molecule. If more wood is harvested at any point

in time in our hectare, more wood framed houses will be built with

contributions coming from our hectare, representing fewer carbon

emissions per hectare.

The substitution numbers are the result of deducting the differential

in carbon emissions from an alternative management scenario with

respect to the 40 Base Rotation. Because the substitution numbers

come from the differential of the Base case to an alternative management

scenario, if no wood is harvested in any of the hectares considered,

there is no difference, they cancel each other out. The differences

only arise when wood is harvested in one scenario and not in the

other one.

4. RESULTS

The alternatives considered characterize the effects of changing

the rotation lengths (the Rotation case) and alternative management

intensities (the Intensity case). A base case scenario is selected

as a reference for the analysis. The rotation analysis compares

the base case to longer rotations, over different periods of time.

The study evaluates carbon pools at the forest and products levels,

and considers trade offs in terms of carbon displacement (fossil

fuel displacement by wood burnt for energy) and substitution in

construction with wood versus steel. The Intensity case assesses

the effects of more intensive management, and trade offs of slightly

longer rotations (10 years) combined with higher management intensities.

The Intensity case, like the Rotation case, provides a detailed

description of the carbon pools and its differences in the forest,

in products, with displacement and substitution impacts. Finally,

the economic implications for these different cases are provided.

4.1 The Rotation Case

The afforestation case is selected as a starting point because

of its tutorial properties and its simplicity. Afforestation implies

the establishment of a new forest on non-forested land. A typical

example of afforestation is to grow trees on degraded agricultural

or pasture land. Afforestation implies a one time increase in the

sink capacity of a certain area, and after the first rotation has

been established and harvested, the development of carbon pools

is similar to a reforestation case.

The base case is selected using LMS and stand inventory data. The

FVS growth trajectory was matched to the McArdle et al.(1949) yield

table for similar stands. In order to create the inventory used

in the rotation and management intensity case scenarios. A newly

created plantation with a base site index of 128 was matched to

the number of trees per acre, the quadratic mean diameter, the height

and volume of a 20 year old stand from McArdle (1949). The FVS PNW

variant was then adjusted to track the change in yield shown in

the McArdle table, by adjusting the maximum stand density index

and growth rates. With the growth model calibrated in such a way,

stands with the same inventory but with different site indexes were

created. An average site index of 110 was picked for the base case

simulation. All of the simulations had a pre commercial thinning

at age 15 and a regeneration harvest at different points in time:

40, 45 and 50 year rotations.

The three rotations were later evaluated for economic optimization.

Zobrist's economic model for the Pacific Northwest region was used

(2001). It provides Soil Expectation Values (SEV) for the scenarios

in question. SEV is a forestry term used to describe "the present

net worth of bare forestland for timber production calculated over

a perpetual series of timber crops grown on that land" (Davis

and Johnson 1986). Maximizing SEV is the correct way of guiding

an investment, and the management decisions to achieve economic

efficiency. The economic model includes management costs and a set

of other variables that must be specified (Appendix D). Assuming

an interest rate of 5%, the 40 year rotation produced the highest

SEV at $463. The forty year rotation therefore was selected as the

base case scenario for both the Rotation and Intensity case scenarios.

The Base 40 year scenario is pre commercially thinned at age 15 to 680 trees per hectare (275 TPA). The 80 year scenario is pre commercially thinned to 680 trees per hectare, and commercially thinned twice, leaving about 2/3 of the total basal area at ages 30 and 60. The 120 year scenario is the same as the 80 year scenario prescription, with one extra commercial thin at age 90. The No Action scenario has nothing done to it and assumes no natural disturbances beyond the normal mortality. All scenarios start with 1900 trees per hectare (770 TPA), and the same number of trees is planted after every regeneration harvest (2.1* 2.4 meter spacing). Regeneration harvest under these scenarios is equivalent to zero retention at time of harvest. The No Action scenario is not equivalent to what one would expect in natural stands since they would generally have had poor stocking and contain many fewer trees per hectare.

Forest carbon results will be presented individually by scenario. Results for the carbon in products, emissions, displacement and substitution will be summarized and compared for the four scenarios combined.

4.1.1 The Forest Carbon

The standing carbon found on site increases from zero in year 2000 to a total of 154 metric tons/ha after the first rotation. By the end of the second rotation, the standing total increases to 182 metric tons/ ha, reaches 191 by the end of the third rotation, and 196 metric tons/ha by the end of the fourth one. Total forest carbon is the amount of carbon found on live and dead components in the last year of the rotation, just prior to the regeneration harvest (Table 5). Trees used for the reforestation simulations (years 2040, 2080 and 2120) are older than the ones planted in the afforestation (2000), therefore slight differences in canopy, stem and live roots can be appreciated in the forest carbon.

| Table 5. Forest carbon in metric tons/ ha prior to final harvest through time. | ||||||||||||||||||||||||||||||||||||||||

|

When compared to the total forest carbon in year 2040, there is an increase of 18% in the total forest carbon at the end of the second rotation, a 24% increase by the end of the third rotation, and a 27% increase by the end of the fourth. The carbon pools are asymptotically approaching a steady state: the reforestation condition starting from the case of afforestation. The carbon in the canopy, stems, snags and live roots reaches this stability more rapidly than the carbon in the dead roots and litter.

The tree stem represents about 68% of the total forest carbon after the first rotation, and because of the increase in the litter and dead root components through time, this percentage decreases to about 60% in the following rotation simulations. It is the increase in the litter and dead root pools that contribute the most to the increase of carbon pools on site.

The numbers from Figure 4 for the forest carbon pools do not correspond to the numbers found in Table 4, since the figure shows the stand after having been harvested in years 40, 80, 120 and 160. This explains the increase in the litter pool and the transfer of the live root carbon pool to the dead root in those particular years. The litter and root pools will eventually reach a stable level in time, as more rotations are grown and harvested.

Soil carbon was not modeled. The way this carbon pool will be affected from the case of afforestation to reforestation, as stated in the Literature review chapter, will mostly depend on the method of harvest and the site preparation activities for the regeneration planting. However, for this evaluation it is assumed that it should have little consequence in the comparisons where the focus is on modest changes between rotation lengths.

|

| Figure 4. Forest carbon pools in metric

tons/ha for the 40 year scenario (after harvests in 2040, 80, 120, 160). |

The forest carbon reaches 228 metric tons/ ha after the second rotation, an increase of 4.5% from the first 80 year rotation (Table 6). The small percentage increase of the forest carbon pool is mainly due to the decomposition of dead roots and litter, with decomposition rates of 5 and 16% per year respectively. The stem, canopy and live roots pools remain relatively constant, when looking at the end rotation results by the end of the second rotation.

| Table 6. Forest carbon in metric tons/ ha prior to harvest through time | ||||||||||||||||||||||||||||||||

|

The increase in the forest carbon pool is due mainly to the increase

in the snag, dead root and litter component (Figure 5). The canopy

carbon pool reaches about 16 metric tons/ ha at age 50 and will

stay relatively constant after that age until harvesting time. The

litter pool increases to 25 metric tons/ha after the first rotation,

and reaches 33 metric tons/ ha after the second rotation. All the

live root carbon is transferred to the dead root pool after harvest,

reaching 44.15 metric tons/ ha after the first rotation and almost

50 metric tons/ ha after the second. It is expected that the litter

and roots carbon pool will reach a stable asymptotic level after

the stand has been carried under this management strategy for several

more rotations.

|

| Figure 5. Forest carbon on two 80 year rotation in metric tons/ha (after Harvest). |

4.1.1.3. The 120 year rotation and No Action scenarios

These two scenarios will be evaluated together in terms of their forest carbon pools. In terms of treatments, the 120 year scenario has had a PCT early in the rotation and three commercial thinnings, therefore the forest biomass and carbon pools will be significantly different. The No Action scenario should not be confused with natural stands, which are generally characterized by poor stocking and periodic disturbances within the first 120 years. The No Action scenario would be subject to a higher risk of disturbances, especially fire and diseases associated with overly dense stands.

There is 13% more carbon in the forest pools of the

No Action scenario than in the 120 year scenario, most of it accumulated

in the stem and live roots, with a difference of 20 and 18% respectively

in those particular components between the two scenarios (Table

7).

| Table 7. Forest carbon pools in metric tons/ ha prior to harvest in 2120, compared to a No Action scenario | ||||||||||||||||||||||||||||||||

|

Not forgotten must be the fact that the 120 year rotation

was commercially thinned three times through the scenario (ages

30, 60, 90): The No Action scenario is above the 120 year scenario

at all points in time due to this fact. The No Action scenario also

has more carbon in snags, which implies the effectiveness and higher

productivities achieved when treatments to reduce competition are

applied (Figure 6).

|

| Figure 6. Forest carbon pools (after harvest in 2120) for the 120 year rotation scenario vs. No Action management scenario (No Action total forest carbon = top line). |

Carbon sequestered in the live roots amount to about

18% of the total carbon in the forest pools in the 120 year scenario,

versus 19.5% of total carbon in live roots pools for the No Action

scenario. There are higher levels of carbon in the litter and dead

root pools in the 120 year rotation because of the different silvicultural

regime. This differentiation starts at the time of the PCT, where

the growth rate for the No Action scenario is still very high. Again,

most of the difference is accounted for by the commercial thinnings

and the differential in the amount of trees per hectare. The No

Action scenario does not seem to have been slowed down by competition,

and mortality seems very low when looking at the total carbon in

the snag component and comparing that number to the snags found

in the 120 year rotation, which is about half, but had four intermediate

operations (PCT and 3 CT).

On a pure forest carbon basis, the No Action scenario forest pools

are greater than any of the other scenarios as a consequence of

the lower removals and higher overall stocking through the management

period considered.

4.1.1.4. Summary forest carbon with different rotations

A summary for the carbon stored in the forest is provided

on a net basis, meaning the carbon emissions coming from silvicultural

operations are calculated and deducted from the total carbon pools

(refer to Methods section for emission calculations). Thus, net

carbon sequestered through the different scenarios is the sum of

the carbon in all live and dead pools through the management period,

with harvest and thinning emissions subtracted.

When considering carbon sequestered in the forest while accounting

for the emissions from operations on site, the No Action scenario

is above any other scenario. The 120 year scenario follows, and

is slightly higher than the 80 year scenario. Last in this list

is the shorter 40 year rotation.

The residual of carbon carried on from one rotation to the next

in the litter, snag and root pools increases from 50 metric tons/ha

to about 70 metric tons/ha in 165 years for all the rotations in

which management comes into place. The results for the increase

in the litter pool assume that no fire is used as a site preparation

tool. Fire would volatilize much of the carbon that is considered

sequestered after the harvest (Figure 7).

Carbon pools are estimated every five years, because there is not

a continuous measure of the inventory in between the five year management

steps simulated. In order to come up with estimates of the areas

under the different curves, the total carbon in the forest pools

at the beginning of each 5-year management step is multiplied times

five and then added together.

|

| Figure 7. Net Carbon in

the forest pools for all rotations through time in metric tons

/ha, with emissions from operations deducted. |

From these calculations, average annual carbon sequestered

in the forest can be estimated for various intervals of time (Figure

8). Periods encompass forty years and do not consider the last harvest

at year 40, 80, 120 or 160 to have been materialized. The Average

carbon in the forest pools is the highest for the No Action scenario,

for any interval of time considered.

|