|

|

|

|

Working Paper 3

Options for Cedar Mill Waste Utilization and Disposal in Western Clallam and Jefferson Counties

Rural Technology Initiative

AcknowledgementsThis report represents a synthesis of information provided from many sources including a review of available literature, pertinent state and federal laws, interviews with individuals, companies, and other organizations. The goal of this investigation, as requested by the Clallam County Economic Development Council, has been to identify environmentally and economically responsible approaches to ensure the viability of the shake and shingle industry in western Clallam County. While the geographical focus of this work has been narrow, it is the belief of the authors that information contained within the following pages will have broader applicability. The project leader and report first author is Larry Mason, Project Coordinator for The Rural Technology Initiative (RTI) at the University of Washington. Members of the research team were John Calhoun, Director of the Olympic Natural Resource Center of the University of Washington, and Bruce Lippke, Professor of Forest Economics at the University of Washington College of Forest Resources and Director of the RTI. This work was made possible by funding provided by the Clallam County Economic Development Council. Active project contributors from the industry and the community that provided input and guidance throughout this investigation included: Tony Romberg (Premium Cedar Co.), John Dematties (Sherico Cedar Products Co.), Jim Haguewood (Clallam Economic Development Council), Rod Fleck (City of Forks), and Bill Hermann (Hermann Logging and Construction Inc.). Of paramount importance for the success of this project was the cooperation received from the many professionals that were contacted within the forest products industry, related industries, and county and city government. No request for information went unanswered. The research team would like to thank Lynne Christensen (Cedar Shake and Shingle Bureau), Gordon McCoy (LP#2 Co.), Charlie Long (Long Cedar Co.), Rob Hart (Long Cedar Co.), Michael Allen (Rejo Cedar Co.), David Haight (Rejo Cedar Co.), Felix Larrechea (Rainy Day Shake Co.), Pancho Leira (ML Cedar Co.), David Hopkins (ML Cedar Co.), Andy Krume (Pacific Cedar Co.), George Powers (Pacific Cedar Co.), Steve Zoffel (Zoffel Log and Mill Co.), Sandy Schier (Silver Moon Accounting Co.), Brent Gagnon (West Waste and Recycling Inc.), Phil Kitchel (Clallam County Economic Development Council - Forest Products Cluster), Edward Tolan (Nippon Paper Industries USA Co. LTD.), Ernie Van Ogle (Kply Inc.), George Cave (Port Townsend Paper Corp.), Bill Quigg (Grays Harbor Paper Co.), Glen Cawley (Grays Harbor Paper Co.), John Pellegrini (Grays Harbor Paper Co.), John McNulty (Local Manufacturing Inc.), Kirk Dalstrom (Viking Lumber Co.), Monte Dalstrom (Dalstrom Lumber Co.), Jim Carlson (Premier Forest Products Inc.), Dean Hurn (Chinook Resources Inc.), Will Possinger (Lincoln Industrial Corporation), Tom Dutcher (EnerWaste International Corp.), Nancy Allison (USDA Natural Resources Conservation Service), and many others. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the authors and do not necessarily reflect the views of the funding agencies or project cooperators. Due to the short time and limited resources available for this investigation, findings should be considered as preliminary pending further study.AbstractFor more than 150 years, the manufacture of shingle and shake roofing materials from western red cedar (Thuja plicata) has been an important industry in western Washington. For decades cedar producers have burned waste wood generated from shingle production in wigwam or cyclone burners. The Olympic Region Clean Air Agency (ORCAA) is one of seven regional air pollution control agencies of Washington State. ORCAA enforcement agents have been working with Clallam and Jefferson County cedar mill owners for several years to bring them into compliance with the regulations that prohibit open burning of mill waste (WAC 173-400-050). State air quality regulations designed to reduce industrial emissions of pollutants could result in closure of operations for 11 small cedar mills currently operating in western Clallam and Jefferson Counties unless cost-effective and environmentally-responsible waste disposal solutions are found as alternatives to burning cedar waste in noncompliant outdoor burners. This report, commissioned by the Clallam County Economic Development Council, characterizes the cedar mill industry in western Clallam County and presents information on options for cedar mill waste utilization and disposal that include; burner upgrades, a centrally located incinerator, pellet manufacture, mulch, animal bedding, road bed material, oil and chemical extraction, chips, and hog fuel. Measures of economic feasibility for disposal/utilization alternatives are developed. A list of available funding and loan programs possibly available to assist with needed financing for mill equipment purchases is reviewed. Increasing government interest in wood utilization for biomass-to-energy and heating systems for public buildings is discussed with suggested connection to utilization of cedar waste as part of a broader regional energy strategy and a local economic development opportunity. Keywords: western red cedar, shingles, shakes, burners, air quality, hog fuel, biomass-to-energy, sustainable development. Executive SummaryBackground Conclusions Ironically, there appear to be broader public costs associated with the potential loss of shingle milling infrastructure that have previously not been considered. Cedar mill closures may mean a lost opportunity to reduce air pollution. Cedar mill waste is an inexpensive biofuel that if used to generate clean electricity would help to reduce state greenhouse gas emissions. Other states have initiated programs, such as Fuels for Schools, to exploit such opportunities to support rural economies while achieving environmental improvements. Increased ability in Forks to utilize wood biomass will support forest management and existing milling infrastructure by creating value for hog fuel. Construction of a biomass-to-energy facility in Forks could also provide new motivation for utilization of old cedar waste piles that pose a potential environmental hazard. Avoided loss of 7 million dollars in tax revenues to local, state, and federal taxing authorities should be considered as a strong economic motivator to invest in hog fuel utilization. Additionally, use of wooden shingles for roofing and siding applications offsets the use of products such as steel, aluminum, and asphalt that are produced from non-renewable resources, are energy-intensive in their manufacture, and subsequently result in comparatively high associated atmospheric emissions. Recommendations Life cycle analysis of carbon emissions comparisons between wood building products and non-wood alternative products shows that when new forest growth, sequestration in forest and product biomass, displacement of fossil fuel energy, and substitution of non-wood products are considered that wood performs much more favorably than other product alternatives (CORRIM 2005). Olympic Region Clean Air Agency (ORCAA) with other appropriate state agency(s) should initiate a life cycle analysis (LCA) study to fully account for the cradle-grave environmental impacts associated with performance of building product alternatives such as cedar shingles as compared to non-wood roofing and siding products. Especially important, as part of this assessment, should be recommendations on how this proven approach to environmental auditing should be best used to inform achievement of state energy policy goals. The findings presented in this report, while preliminary, suggest that there is unique potential for biomass-to-energy development in Forks as part of the broader state and national energy plan to expand use of renewable resources and reduce greenhouse gas emissions. Representatives from the City of Forks, the Clallam County Economic Development Council, The Clallam Public Utility District, ORCAA, and representatives of other appropriate county, state, and federal agencies as well as other interested parties should review the data and assess the merits of this hypothesis. The authors recommend that a feasibility study should be initiated to more definitively portray the costs, benefits, and potential magnitude of biomass-to-energy development in Forks. Given that July 2005 is very near and that there appears to be a potential for unintended consequences with potentially grievous social, economic, and environmental results, the authors recommend that the existing burners be temporarily granted a release from the July deadline pending the completion of the studies suggested above and any subsequent pursuit of biomass-to-energy development opportunities in Forks. In the interim, however, no expansion of existing burning activities or new construction of burners should be allowed.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Figure 1 | Workers preparing shingle bolts at a Washington mill about 1915. Photographers: Webster & Stevens. From the collection of the Museum of History and Industry. Used with permission. |

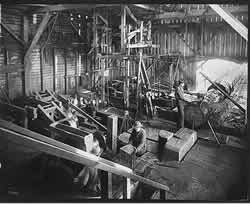

| Figure 2 | 1907 shingle mill. Photographer unknown. From the collection of the Everett Public Library. Used with permission. |

| Figure 3 | Shingle saw. 1907. Photographer unknown. From the collection of the Everett Public Library. Used with permission. |

| Figure 4 | Shingle packers in Snohomish County mill. 1910. Photographer unknown. From the collection of the Everett Public Library. Used with permission. |

| Figure 5 | Seaside Shingle Mill. Everett, WA. 1915. Photographer: Juleen. From the collection of the Everett Public Library. Used with permission. |

| Figure 6 | Western Clallam County |

| Figure 7 | Cedar Shakes |

| Figure 8 | Aerial view of Forks, WA. with 4 of the shingle mills in the lower left and the Olympic Natural Resource Center (UW satellite campus) in the lower right. |

| Figure 9 | Shingle mill burners in western Clallam and Jefferson Counties. |

| Figure 10 | Composition of Cedar Mill Residues, 1988 - 2000 (Larson 2000, with Mason estimate) |

| Figure 11 | Old waste compared to fresh mill waste. Note the lack of bark and chunks in current material on right. |

| Figure 12 | Wood pellets |

| Figure 13 | Western red cedar chips |

| Figure 14 | Raw Shingle waste on the left compared to hogged shingle waste on the right. |

| Figure 15 | Chip van receiving shingle waste at Premium Mill in Beaver, WA. |

| Figure 16 | Emissions comparisons for wood and non-wood alternatives (from Richter 1998 in IEA 2000) |

| Figure 17 | Automated wood chip conveyor Darby School District. Darby, Montana. Source: Forest Service. |

| Figure 18 | The impact of biomass fuel cost on the cost of energy. Source: McNeil Technologies, Inc. 2003. |

| Figure 19 | Removing bales of forest biomass during forest thinning activity. Source: McNeil Technologies, Inc |

List of Tables

| Table 1 | Estimated Production, Employment, Sales, and Taxes for the Forks Cedar Industry. |

| Table 2 | LBS. of Carbon Emissions Avoided by Burning One Ton of Pellets Verses Alternatives. |

| Table 3 | Heating values for the wood of some NW species in BTU/ovendry ton (Ince 1979). |

| Table 4 | Cedar Waste Test Results (associated with Table 5) |

| Table 5 | Cedar Waste Test Results (associated with Table 4) |

| Table 6 | Comparisons of debt burden for different principles & interest rates for 5 year notes. |

| Table 7 | Comparative fuel costs 2003. |

Introduction

The Olympic Region Clean Air Agency (ORCAA) is one of seven regional air pollution control agencies located throughout Washington State. ORCAA has regulatory and enforcement authority in and for Clallam, Grays Harbor, Jefferson, Mason, Pacific, and Thurston counties and is responsible for enforcing federal, state and local air pollution standards and governing air pollutant emissions from new and existing sources. The agency operates under the authority of the Clean Air Washington Act (RCW 70.94). A nine member Board of Directors establishes the policies and oversees the operation of the agency. ORCAA enforcement agents have been working with Clallam and Jefferson County cedar mill owners for several years to bring them into compliance with the regulations that prohibit open burning of mill waste (WAC 173-400-050). ORCAA has set a final deadline for compliance on July 1, 2005 after which cedar mill owners/operators may be subject to penalties and other enforcement action if wood waste burning is not stopped or waste burners are modified/replaced to meet federal performance standards. Enforcement of state air quality regulations designed to reduce industrial emissions of pollutants could result in closure of operations for some or all of the 11 small cedar mills currently operating in western Clallam and Jefferson Counties unless cost-effective and environmentally-responsible waste disposal solutions are found as alternatives to burning cedar waste in noncompliant outdoor burners.

In March of 2005, the Clallam County Economic Development Council, in hope of finding acceptable solutions for the disposal of cedar waste that could minimize negative social and economic impacts to the Forks area, while meeting state regulatory goals, asked a team of researchers from the University of Washington to quickly initiate a study to explore and inform them of any viable options. The following report presents study findings based upon best available information that will:

- Characterize the cedar mill industry in Clallam County.

- Document and quantify the problem.

- Identify and characterize systems for processing and handling cedar mill waste.

- Develop operational and economic information about the most promising systems.

- Identify and describe financing opportunities for cedar mills to capitalize required modifications to mill operations.

| C. Larry Mason Project Coordinator Rural Technology Initiative College of Forest Resources University of Washington Seattle, WA 98195-2100 |

John Calhoun Director Olympic Natural Resource Center College of Forest Resources University of Washington Forks, WA 98331 - 9383 |

Bruce Lippke Director Rural Technology Initiative College of Forest Resources University of Washington Seattle, WA 98195-2100 |

Background

Ralph Andrews (1994) tells us that it all started in the early 1880’s along the Columbia River. At first, there were little hand machines operating along the edges of the wet forests of virgin cedar. The product was thin, light, and strong. It was used on roofs because it would shed rain and snow and last a long time. The product was a cedar shingle and it delivered such good building value that the business of cutting shingles became a major industry in the Pacific Northwest. By the time that the Northern Pacific Railroad arrived on the coast and production machines were introduced, the shingle milling industry was growing fast. In 1893 there were 150 mills manufacturing shingles in Washington. Shingles were shipped overland by rail, and by water freight on schooners bound out of the Columbia River and Puget Sound.

Many mills were powered by water wheels through the early 1900’s. Later the larger mills turned to steam power generated from burning wood waste to run the machinery and dry the product.

|

| Figure 1. Workers preparing shingle bolts at a Washington mill about 1915. Photographers: Webster & Stevens. From the collection of the Museum of History and Industry. Used with permission. |

In the woods, shingle bolts were cut to 52 inches long from large diameter cedar logs with 20 – 40 bolts to the cord. Bolts were skidded by horse, rafted in booms, and floated down flumes. Cut off saws chopped bolts or logs into 16”, 18” and 24” lengths. Blocks traveled by conveyor to quartering saws that cut across the diameter to give blocks proper size and an opening face of vertical grain from which the sawyer might start the first cut. Additional saws trimmed off bark and surface defects before the prepared shingle blocks traveled to the second floor and the shingle machines. Blocks were placed in machines where saws cut against the face, shifting backward and forward, canting top and bottom. The carriage moved the block past the saw to create a tapered shingle that might have been 3/8” on the butt and 1/16” on the tip. As fresh shingles came from the machine, “knot sawyers” squared edges and trimmed any defects. Grades were segregated by quality and dumped down chutes into bins located on the floor below. Packers assembled bundles, each to contain ¼ of a square or 25 square feet of roof coverage. There was no nonsense. Workers were paid on piece work.

| Figure 2. 1907 shingle mill. Photographer unknown. From the collection of the Everett Public Library. Used with permission. |

Bundles were secured with iron straps and strips of hemlock. Conveyors took the finished bundles to dry kilns where a slow steam process dried the shingles over a period of ten days to two weeks. Waste wood was burned as fuel in huge burners to generate the steam to power the mill, dry the product, and generate electricity. Smoke as a negative consequence of wood burning was not a consideration in this logical and efficient utilization arrangement.

| Figure 3. Shingle saw. 1907. Photographer unknown. From the collection of the Everett Public Library. Used with permission. |

| Figure 4. Shingle packers in Snohomish County mill. 1910. Photographer unknown. From the collection of the Everett Public Library. Used with permission. |

| Figure 5. Seaside Shingle Mill. Everett, WA. 1915. Photographer: Juleen. From the collection of the Everett Public Library. Used with permission. |

During the first half of the twentieth century the mills grew

bigger and bigger. For example, the M.R. Smith Shingle Co. became

a formidable manufacturing organization on the Olympic Peninsula

that owned several mills. Until the early 1970’s, M.R.

Smith Shingle Co. operated the largest steam-powered shingle

mill in the world. It was located on Lake Pleasant in Beaver,

Washington. Logs entered the mill from the lake via the log slip

and were cut into blocks that went to be sawn by ten shingle

machines that operated two shifts. In 1966, the Smith mill at

Beaver produced 132,544 squares of shingles (Maunder and Holman

1975). As reference, a fair-sized home might require 20 square.

There have been many changes for the shingle industry over the

last 100 years. It is a safer industry; a mature industry. It

is a much smaller industry both in overall capacity and size

of manufacturing facilities. Today the combined production of

all operating mills on the northwestern peninsula is substantially

less than that achieved singly by the M.R. Smith Beaver mill

some forty years ago. Most of today’s shingle cedar comes

as 16 to 24 inch long blocks cut from salvage activities that

clean up the leavings of long-previous timber harvesting activities.

The glory has faded but the hard work continues with today’s

shingle “weavers” dedicated more to survival than

to achievement of heady levels of production. Very little cedar

is available any more from public forests. Raw materials must

come almost exclusively from private salvage and are often in

tight supply. To make matters worse, smoke from waste burners

has now become a serious problem that must soon be solved.

No longer is shingle waste burned to generate steam. Electricity does the job instead. Today mill waste, once a resource, has now become a garbage problem. Public concerns over air pollution signal that the time of the unregulated burner is coming to a close. The Olympic Region Clean Air Agency (ORCAA) is a multi-county governmental agency established by Washington State law (Revised Code of Washington (RCW) 70.94) to regulate businesses which emit air pollutants in Thurston, Clallam, Jefferson, Grays Harbor, Mason, and Pacific counties in accordance with the Washington State law WAC (173-400) and ORCAA Regulation 1. For several years ORCAA representatives have been corresponding with shingle mill owners to urge modifications to waste disposal strategies that will bring mills into compliance with state air quality regulations. In July 2005, burners that do not comply with current state air quality regulations appear to be scheduled for enforced shut down. In mid March 2005, the Clallam County Economic Development Council, realizing that no solutions were forthcoming, asked the Rural Technology Initiative (RTI) and the Olympic Natural Resource Center (ONRC) at the University of Washington College of Forest Resources to help inform choices by quickly developing characterizations of alternative strategies for disposal of cedar waste in western Clallam County. An investigation was begun in April 2005.

The Shingle Industry in Western Clallam County 2005

In order to better understand the magnitude of the cedar waste disposal problem, it was determined that a qualified characterization of this local industry should be undertaken by the investigation team. Representatives from the milling companies were interviewed. Reference materials provided by the Cedar Shake & Shingle Bureau, government publications, and from the literature were reviewed to estimate industry production, revenue, employment, and tax contributions.

Figure 6. Western Clallam County |

Washington Department of Natural Resources (DNR) Mill Survey Reports show a state drop in shake and shingle production of more than 80% between 1986 and 1998 (Larson 2003, 2000, 1998, 1992). In western Clallam County where more than 100 mills operated 20 years ago, 11 mills were found to be in operation today. Mills range in size from one shingle saw to three shingle saws. A tally of all saws in area mills indicates that there are a total of 17 shingle and Figure 6. Western Clallam County 6 shake saws that are available for production. Some mills, however, operate intermittently due to insufficient available cedar raw material needed for shingle manufacture. |

Mills report that direct manufacturing employment can vary between 55 – 63 full time jobs/year. The total estimated employment in contract-support positions such as block cutters, truckers, helicopter operators, pallet makers, accountants, and others is approximately 130 additional jobs. All jobs in the woods, the trucks, and the mills can be considered direct employment. Since there is little automation incorporated into any of these cedar enterprises, it is logical to expect that job multipliers might be higher for this industry sector than for others. With that in mind, employment estimates based upon mill interviews were compared to employment multipliers for the forest products industry that have been developed in the literature. Warren (2004) estimated direct forest industry employment in Washington and Oregon at 13.2 workers/MMBF of annual timber harvest for the year 2002. Han et al. (2002) suggests that, depending upon the availability of paper industry jobs, the number of direct jobs in Idaho may fluctuate from 9 to 11 forest products workers/MMBF of harvest/year. Keegan et al. (2004) found that harvest and processing saw timber generates 9 direct full-time jobs per MMBF per year in Montana. In addition to direct forest industry employment, there are many more indirect jobs that also result from timber harvest that provide benefits throughout the state. Conway (1994) developed a regional interindustry econometric model called the Washington Projection and Simulation Model (WPSM) and estimated the total direct and indirect jobs per year created from one million board foot of timber harvest in Washington State in 1992. Conway found that for every direct industry job/MMBF/year another 4.2 indirect jobs were created. He estimated that for 1992 there were 7.7 direct jobs and 32.3 indirect jobs linked to each MMBF of timber harvest. The Conway WPSM is used here to estimate magnitude of direct and indirect employment. For the 11 shingle mills that make up the cedar industry in the Forks area, the WPSM calculation indicates there should be 121 – 141 direct jobs/year and 509 – 591 indirect jobs/year. While indirect job multipliers require econometric models to estimate employment impacts, a comparison for reasonableness can readily be made for direct job estimates offered by mill owner and estimated direct jobs from WPSM. Total reported direct jobs/year are approximately 185- 193 including all woods and transportation support positions. The WPSM estimate of 121-141 direct jobs/ would appear, as expected given the labor-intensive nature of this industry, to be conservative.

Figure

7. Cedar Shakes. Figure

7. Cedar Shakes. |

Assuming an average wholesale price of $100/square of shingles, the combined gross sales value derived from sale of all products produced by the mills of interest would be $10,072,800 - $11,704,800/year. In addition, significant public benefits are derived through the generation of local, state, and federal tax revenues. Local and state tax benefits are calculated at 11% and federal taxes are calculated at 19% of the Gross State Product (GSP) (Lippke et al. 1996). Using $40,000 as a low approximation of the additional state economic activity added to the GSP Figure 7. Cedar Shakes. from each cedar-related job, an estimate of the GSP and associated local, state, and federal tax revenues can be developed from the jobs-to- |

Table 1. Estimated Production, Employment, Sales, and Taxes for the Forks Cedar Industry

Production (cords/year) |

Production (sq/year) |

Gross sales |

Employ (direct) |

Employ (indirect) |

Gross State Product |

State & Local Taxes |

Federal Taxes |

13,121-15,281 |

100,728 - 117,048 |

$10,072,800 - $11,704,800 |

121-141 |

509-591 |

> $24,000,000 |

>$2,640,000 |

>$4,560,000 |

In isolated areas, such as Forks where jobs can be scarce, the social and economic contributions of small businesses leverage higher than for urban counterparts. A University of Washington examination of State urban and rural per capita income from 1979-1997 (CINTRAFOR, 1998) found that increasing urban to rural income disparity in Washington State had reached 66%. Additionally significant to western Clallam and Jefferson Counties is the fact that the shingle industry provides unique employment opportunities for minorities and otherwise marginally employable persons.

| Figure 8. Aerial view of Forks, WA. with 4 of the shingles mills in the lower left and the Olympic Natural Resource Center (UW satellite campus) in the lower right. |

Financing

Conversion of mill facilities to discontinue burning on site and to accommodate any new combination of processing and transporting will require capital investment. This section of the report will document the results of our research into the options for capitalizing mill conversions.

Commercial Lenders

Several commercial lenders serve western Clallam and Jefferson

County. Various lending products are available. Regional lending

institutions were contacted and asked to provide information

relative to commercial loans suitable for investments in industrial

equipment and modifications that could be needed for cedar

waste system conversions. Bank of America, Sterling Saving

Bank, Frontier Bank and First Federal Savings and Loan provided

data. Borrowers with existing relationships with lenders (business

checking accounts, commercial line of credit, etc.) generally

can obtain more favorable terms then new customers. Commercial

loans are available with terms of from one to five years and

interest rates from 6.5% to 12%. While some lenders surveyed

offer longer amortization of 20 or more years, loans longer

than 5 years would likely outlast the life of the equipment

and therefore be unsuitable for this application. Collateral

for these loans include the underlying real estate. Loan fees

of 1% or more are sometimes required. Loan conditions vary

depending upon credit rating, cash flow, collateral and other

variables.

Evergreen Community Development

The Evergreen Community Development Company is certified and

regulated under the Small Business Administration to make Section

504 loans in the geographic areas of Alaska, Washington, and

parts of Oregon. Section 504 loans are a partnership between

Evergreen Community Development and a local lender providing

funds up to 90% of the total costs for building or equipment

purchase. The purpose of the program is to “expand small

businesses” and “preserve working capital”.

Loans are recommended to be in excess of $200,000 but lower

amounts are also available. Businesses that are required to

purchase equipment because of changing state or federal regulations

automatically qualify for these loans. Funds are made available

for real estate and equipment purchase only; rolling stock

does not qualify for financing under this program. Loans offer

long term repayment schedules of from 10 to 20 years. Interest

rates are fixed for the life of the loan. The rate is negotiated

with the participating bank at market rates. http://www.sba.gov/financing/sbaloan/cdc504.html

The Rural Loan Program, available through Evergreen Community Development is administered in partnership with the US Department of Agriculture and offers loans to businesses in rural communities in amounts from $10,000 to $250,000. Businesses located in rural areas of less then 25,000 people and certain counties in Washington State qualify. Western Clallam and Jefferson county businesses qualify under this program. The program requires 25% down for purchase of equipment and related installation costs but offers long repayment schedules at competitive interest rates.

Both of these programs can be accessed through Evergreen Community Development at 1-800-878-6613 or through their web site http://www.ecda.com.

Cascadia Revolving Fund

The Cascadia Revolving Fund manages the Olympic Microloan Fund.

The fund provides loans and technical assistance to small businesses

that are unable to obtain financing through conventional sources.

The Counties sponsoring the Olympic Microloan Fund are Clallam,

Grays Harbor, Island, Jefferson, Mason, Pacific, San Juan,

Thurston and Wahkiakum.

Under this program borrowers must have no more then 5 full time employees or equivalent. The income level of the business owners must fall within certain guidelines (relatively low levels). Loan amounts range from $1000 to $25,000, the average fixed rate is 10% and the terms range from 1 to 5 years. Loans can be used for operating costs, purchase of equipment and fixtures, debt refinancing and real estate acquisition.

Cascadia also manages the Forks Revolving Loan Fund. This program is privately funded and designed to offer customized loans to small businesses in the Forks area. The total amount available to loan to all applicants in this revolving loan fund is approximately $25,000. Local administration of this fund is provided by the City of Forks. Rod Fleck or Dan Leinan can be contacted at Forks City hall (360-374-5412).

The Cascadia Olympic Microloan Fund manager is Ruth Ann Halford.

She can be reached at 206-447-9226 ext. 113. Additional information

can be found on the web at

http://www.cascadiafund.org/omf.htm

ShoreBank Enterprise Pacific

The ShoreBank Enterprise Pacific is a private organization that

has been active in Southwest Washington making traditional

and non-traditional loans to rural, resource dependent businesses

and others. They have recently made a commitment to begin lending

activities in the North Olympic Peninsula, particularly Clallam

County. Loan terms and conditions are negotiable but are similar

to programs offered by Cascadia and Evergreen Community Development.

ShoreBank Enterprise Pacific is managed by Mike Dickerson.

He can be reached at 360-642-4265. More information is available

on their web site, http://www.sbpac.com.

Washington State Department of Community, Trade and Economic

Development (CTED)

This state agency administers a number of community development

and business assistance loan and grant programs. Their web site,

www.cted.wa.gov features a “Guided Search for Services,

Grants and Loans.” Our search of this site revealed that

CTED may have direct loan or grant programs for the purposes

for which cedar mills require. Several CTED loan programs are

listed below. Letters of support to other lenders or grant sources

and other non-tangible assistance may be available. The Director’s

office can be reached at 360-725-4000.

Rural Washington Loan Fund (a CTED program)

The Washington State Rural Washington Loan Fund (RWLF) provides

gap financing to businesses which will create new jobs or retain

existing jobs, particularly for lower-income persons in rural

counties. “Gap” is defined as that portion of a

project which cannot be financed through other sources, but

which is the last portion needed before the overall investment

can occur. Priority is given to timber-dependent and distressed

area projects. Loan amount is determined by the “gap” and

competitive factors, and cannot exceed one-third of the total

project costs. Loans can be secured up to $700,000 with Director's

approval. Funds can be lent for the acquisition, engineering,

improvement, rehabilitation, construction, operation, or maintenance

of any property, real or personal, that is used or is suitable

for use by an economic enterprise. Working capital term loans

are eligible costs. For information contact Steve Saylor at

(360) 725-4046. http://qa.cted.wa.gov/portal/alias__cted/lang__en/tabID__87/DesktopDefault.aspx

Forest Products Revolving Loan Fund Program (a CTED program)

The Forest Products Revolving Loan Fund (RLF) Program is designed

to finance projects which implement value-added production

processes. Financial assistance is available to eligible forest

products firms only in the State of Washington. The RLF program

provides matching loans to qualified small and medium-sized

forest products manufacturing firms to finance projects that

contribute to the diversification of the forest projects industry.

A contract packager works with the applicant to assemble the

application materials including financials, business plans,

and credit analysis. Loan processing of approved applications

is completed by program staff. After closing, loan payments

are made through a contract loan servicer. Loans are available

to meet most financing needs. Typical loans are used to finance

purchase of machinery, equipment and fixtures, real estate,

engineering costs, construction, inventory purchases, and working

capital loans. Loan must be matched 1:1 by non-federal funds.

The minimum loan size is $50,000. The maximum loan size is

$1,000,000. There are a number of fees including a processing

fee, packaging fee, and additional fees may include UCC searches,

real estate title searches, and title insurance. The term of

the loan and the interest rate are negotiable.

The applicant must have sufficient management experience and

technical ability, have a satisfactory credit and personal history

and have a reasonable amount of equity in the business. The business

must show adequate repayment ability and must be willing to pledge

available collateral. Phone Steve Saylor at 360.725.4046

http://qa.cted.wa.gov/portal/alias__cted/lang__en/tabID__91/DesktopDefault.aspx

SBA Loans and Loan Guaranties

When lenders wish to reduce the risk factor in loans to small

businesses, the U.S. Small Business Administration (SBA) programs

offer a way to lower the risk factor to an acceptable level.

The most common SBA loan is the SBA 7(a), or Guaranty Loan.

Under this program, the lender lends its own funds and the

SBA guarantees up to 85 percent of the loan against default.

In addition to reduced risk to the lender, the lender may sell

the 85 percent guaranteed portion of the 7(a) loan on the secondary

market. This makes SBA programs even more attractive to lenders.

All banks are eligible to participate in SBA programs. The

7(a) program is SBA's best means of helping small firms obtain

long-term financing for business needs such as working capital,

machinery, equipment, furniture, fixtures, leasehold improvements,

building acquisition or construction, and in some cases, debt

consolidation. The interest rate on SBA 7(a) loans is usually

a variable rate that floats between 2 percent and 2 3/4 percent

over New York PRIME. The loan term varies depending on the

purpose and collateral. For example, a working capital loan

would carry a maximum term of 7years; a real estate loan could

carry a term of 25 years; and a working capital and real estate

loan could carry a combined term of 15 years. In most cases,

the maximum SBA loan guarantee is $1,000,000.

http://www.sba.gov/financing/sbaloan/7a.html

Northwest Business Development Association

NWBDA is private lending company managed by a team of finance

professionals that are licensed by the U.S. Small Business

Administration to administer the 504 loan program in the state

of WA and five counties in North Idaho. NWBDA has Business

Development Officers in Spokane, Seattle, Central Washington

and the Vancouver / Southwestern areas to serve small business

needs. A board of directors, composed of experienced community

and business leaders, oversees the company. Phone 425-235-9917

or 425-235-9918. http://www.nwbusiness.org/index.ydev

USDA Business and Industry Guaranteed Loans

The Business and Industry (B&I) Guaranteed Loan Program helps

create jobs and stimulates rural economies by providing financial

backing for rural businesses. This program provides guarantees

up to 90 percent of a loan made by a commercial lender. Loan

proceeds may be used for working capital, machinery and equipment,

buildings and real estate, and certain types of debt refinancing.

The primary purpose is to create and maintain employment and

improve the economic climate in rural communities. This is achieved

by expanding the lending capability of private lenders in rural

areas, helping them make and service quality loans that provide

lasting community benefits. This program represents a true private-

public partnership.

B&I loan guarantees can be extended to loans made by recognized commercial lenders or other authorized lenders in rural areas (this includes all areas other than cities or unincorporated areas of more than 50,000 people and their immediately adjacent urban or urbanizing areas). Generally, recognized lenders include Federal or State chartered banks, credit unions, insurance companies, savings and loan associations, Farm Credit Banks or other Farm Credit System institutions with direct lending authority, a mortgage company that is part of a bank holding company, and the National Rural Utilities Finance Corporation. Other loan sources include eligible Rural Utilities Service electric and telecommunications borrowers and other lenders approved by RBS who have met the designated criteria.

Assistance under the B&I Guaranteed Loan Program is available to virtually any legally organized entity, including a cooperative, corporation, partnership, trust or other profit or nonprofit entity, Indian tribe or Federally recognized tribal group, municipality, county, or other political subdivision of a State.

The maximum aggregate B&I Guaranteed Loan(s) amount that can be offered to any one borrower under this program is $25 million. More information about this program can be obtained from the Natural Resources Conservation Service Rural Development Conservation District in Port Angeles, WA. by calling 360-452-8994 or visiting the national web site at http://www.rurdev.usda.gov/or/gbi.htm .

Small Business Loan Research for a Fee

Several fee-for-service businesses are available to assist small

businesses in finding loan programs or grants. These are not

government programs but private, internet-based businesses

that can help locate loan programs, assist in making applications

and manage processing of loans or grant applications. Fees

are charged depending upon the service rendered. One such service

for fee business is http://www.smallbusinessloans.com. This

business claims, “Our specialty is securing you the lowest

rate and best term with the least documentation required.”

Summary of Selected Loan Programs

Several loan programs have been identified above as designed

to benefit the environment, sustain small businesses, create

or protect jobs in areas affected by declines in the forest

industry, and/or create new forest products related jobs. There

are many programs (private, state, federal, and not-for-profit)

and further research may reveal that this list is not complete.

As a cautionary note to mills considering beginning application

for business financing; loan application processes can be time-consuming,

costly, and often require months to complete. Advice from your

local lender and the Clallam County Economic Development Council

will be well-advised.

| Figure 9. Shingle mill burners in western Clallam and Jefferson Counties. |

Cedar Waste

The composition of cedar waste generated from shingle manufacture

has changed over time (Larson 2000). Today sawdust and shingle

tow are the dominant portion of mill waste, while the percentage

of bark and chunks has gone to nearly zero. These changes are

largely a result of the industry shift to an almost exclusive

use of salvaged blocks rather than large diameter logs. With

public timber declines in the 1990’s, very few logs were

available for purchase. Blocks are often salvaged by independent

cutters that sling small piles with poly ropes and employ the

services of a helicopter to “fly” the blocks to

a landing for transshipment by truck to the mill. Every effort

is made to trim blocks clean to reduce expense from the woods

to the mill. Figure 10, below, shows how the composition of

cedar mill waste has changed over time from 1988 -2000.

|

| Figure 10. Composition of Cedar Mill Residues, 1988 – 2000 (Larson 2000, with Mason estimate) |

| Figure 11. Old waste compared to fresh mill waste. Note the lack of bark and chunks in current material on right. |

Utilization and Disposal Options for Cedar Mill Waste

Burner Upgrades

Several companies fabricate and sell burners that could be

acceptable to meet state air quality standards. Representatives

from Heuristic

Engineering Inc., EnerWaste International Corp. and Lincoln

Industrial Corp., Inc. were contacted and interviewed (Lefcourte,

Possinger,

and Dutchers per com). Burner replacement costs are estimated

to begin around $100,000 with cost magnitude increasing with

capacity need. Burner upgrades (retrofits to existing equipment)

to meet current air quality standards may be possible for mills

with Olivine burners that are in good condition (Dutcher pers

com). Cost estimates for retrofits are problematic and can

only be determined on a case by case basis after inspection

by a qualified

engineer. Many existing burners were locally fabricated and

are unlikely to be suitable as upgrade candidates. A cautionary

note

expressed by professional burner representatives is that there

is no absolute way to know that equipment will pass state air

quality tests prior to investment and installation. While more

thorough study would be helpful to determine the feasibility

of burner upgrades or replacements, based upon preliminary

information, submitted above it, would seem unlikely from

both an engineering

and cost perspective that this option could be pursued by mill

owners.

Centrally Located Incinerator

It has been suggested that financial resources from multiple

mills could be combined to underwrite costs of the establishment

of a centrally located modern burner that would meet regulatory

standards. Operations and maintenance costs would be met through

collection of tipping fees for mill waste deliveries. A feasibility

study would be required to determine if this option is affordable

and realistic. The Energy and Environmental Combustion Laboratory

in the Department of Mechanical Engineering at the University

of Washington (de Brun Kopts and Malte 2004) has conducted

research into wood waste combustion that may be helpful if

further consideration of this option is determined to be warranted.

However, in addition to the caveats mentioned for the previous

option, a centrally located incinerator would add another variable;

unprecedented reliance of one mill upon another. The economic

viability of such a centrally located incinerator, whether

constructed as a cooperative or as entrepreneurial venture,

would always be dependent upon the performance and survival

of the worst operator. No investor(s) has been identified with

interest in developing a for-profit centrally located incinerator.

As well, no enthusiasm for this option was found to be present

among mill owners.

Pellet fuel is made mainly of sawdust, shavings, and fines that result as a residual byproduct of lumber manufacture. Pellet manufacturers require fine ground wood particles as feedstock. Material is dried, compressed, and extruded into

| small eraser-sized bits. A similar process

is used to manufacture some types of animal food. Pellets

have become a popular heating fuel for residential and commercial

applications. Pellets are highly combustible and produce

little smoke or ash. Some consumers choose pellets as a heating

alternative to reduce consumption of fossil fuels. Table

2 below displays estimates developed by the British Columbia

Pellet Manufacturers Association (BCPMA 2005) for the pounds

of carbon emissions that are avoided when pellets are burned

displacing use of other energy alternatives. BCPMA claims that if every household in the United States converted to wood pellets for heating, the total carbon emissions for the nation would drop by more than 8%. |

Table 2. LBS. of Carbon Emissions Avoided by Burning One Ton of Pellets Verses Alternatives.

LBS. of Carbon Emissions Avoided by Burning One Ton

of Pellets Verses Alternatives |

|||

Electricity |

Oil |

LPG |

Natural Gas |

3323 |

943 |

709 |

549 |

Pellet manufacture would appear to be a potential long-term and environmentally responsible option for utilizing cedar waste as well as other locally available volumes of hog fuel. Forks would appear to be well-positioned with access to inexpensive residual wood waste. However, a closer look reveals that there may be serious challenges to the feasibility of locating a commercial pellet manufacturing facility in Forks. The only manufacturer of pellets in western Washington is Manke Lumber Co. in Tacoma which produces 30,000 tons of bagged pellet stove fuel each year. Manke is an example of onsite high volume utilization of manufacturing waste to recover value. This situation is dissimilar to the waste problem confronted by cedar mill owners. According to published reports, U. S. market demand for pellets has leveled off in recent years. Future market elasticity to support increased pellet production in western Washington as a cedar waste utilization option can not be assured. Questions of sufficient volume of suitable wood waste available in the Forks area to support profitable pellet manufacture at scales needed to support investment (assuming receptive market) need close examination. Pellets are a low margin and high volume product that must be shipped to distant customers. Transportation isolation may pose a challenge to successful pellet manufacture. The closest railhead to Forks is one hundred miles away in Hoquiam/Aberdeen. The authors are not aware of private investors that currently have interest in pellet manufacture in Forks.

Mulch

A quick search of the internet found 3 western Washington garden

products companies that offer cedar chips and hog fuel for

sale on a retail basis. All companies are located distant from

Forks in the Puget Sound area. Anecdotal information, however,

suggests that cedar, because of its slow rate of decomposition

and caustic oils, would not be a preferred soil supplement.

Interviews with Washington landscapers were conducted as part

of a prior cedar waste feasibility study in Grays Harbor County

(Cascadia Consulting Group and Re-Sourcing Associates 1999).

Results showed agreement that cedar is a poor soil amendment

and may actually inhibit garden plant growth. This same study,

however, does suggest that there is a market on the east coast

for cedar bark mulch because of its visual appeal to customers.

Western Clallam cedar waste has very little bark. Cedar waste

must be hogged to be offered as mulch. Transportation isolation

of Forks mills would compromise access to distant markets.

While results of this quick study may not be conclusive, the

investigation team located no wholesale market available to

shingle mills for cedar mulch.

Animal Bed Material

Attributes that make cedar desirable for use as animal bedding

include absorption characteristics and appealing natural aroma.

Cedar that is to be used for animal bedding must be chipped

or ground to small piece sizes and is preferred to be dry.

Reports also indicate that cedar may provide pesticidal benefit

by repelling fleas, mites, and other insects. Evidence suggests

that cedar bedding decreases incidences of foot rot in cattle.

However, studies have also shown that cedar if ingested can

have harmful effect on animals and humans that eat them. Fine

slivers present in ground cedar have been known to irritate

live stock (Cascadia Consulting Group and Re-Sourcing Associates

1999). Cedar waste must be ground into hog fuel to make animal

bedding. While results of this quick study may not be conclusive,

the investigation team located no wholesale market available

to shingle mills for animal bedding.

Cedar Oil and Chemicals

Cedar is famous for its rot resistant and aromatic properties.

Extractives can be obtained by hot water extraction and are

readily separated into volatile (1.0 – 1.5% of the heartwood)

and non-volatile fractions (5 – 15%) by steam distillation

(Barton and McDonald 1971). The volatile fraction consists

of thujaplicins, thujic acid, and methyl ester. The thujaplicins

and thujic acid are natural fungicides. The thujaplicins especially

are highly toxic to wood-destroying fungi comparable to the

toxicity of sodium pentachlorophenate. Methyl thujate is one

of the extractives that gives cedar its characteristic odor

(Barton and McDonald 1971). During the 1980’s there was

actually a small company on the western Olympic Peninsula called “Cedar

al” that experimented with cedar oil extraction for purposes

of making an aromatic spray. While this company was able to

successfully extract cedar oil it was unable to remain in business.

More recently, two companies, Forest Pacific Biomass Corp from

Washington and Xylon Biotechnologies Ltd. of British Columbia,

have been to the peninsula to express interest in utilization

of cedar waste for oil and chemical extractions to be used

for fragrances and medicinal applications. There has been no

evidence, however, of investment willingness beyond discussion

but it may not matter for the issue at hand.

Several logistical factors are worthy of note as the suitability of cedar oil extraction is considered relative to the shingle waste problem. It is uncertain whether speculated cedar oil extraction operations would require volumes of waste equal to mill disposal needs. More importantly, however, if cedar oil extraction activities were to be initiated in western Washington, chips would logically be the preferred raw material not mill waste. Chips are uniformly sized for ease of handling and, once the oil is removed, chips can be resold for paper manufacture at the same price at which they were purchased resulting in a zero raw material cost. This would not be the case with shingle waste which would need to be hogged and then sent to a paper mill at a loss. A cedar oil extraction plant would logically be located near a cedar lumber manufacturer that could produce needed chip supplies. It has been more than ten years since there was a cedar saw mill operating in Forks.

Chips| Cedar chips are a valuable product that can

bring a net revenue return to cedar chip producers. Chips

must be sized during manufacture to meet strict paper company

specif- ications. During the chipping process over-sized and under-sized pieces are removed through screening. This material becomes hog fuel which is a lower value product used for fuel not paper fiber. Port Townsend Paper Corporation requires that 20% of all its chip consumption be cedar. The long fibers, unique to cedar chips, are needed for the manufacture of the kraft pulp and unbleached paper products that are made by this company. Chips must be sized to approximately 7/8 inch long by 3/8 inch thick. Manufacture of chips requires solid wood from chunks or logs. Equipment needed to manufacture chips can be costly; well over $100,000. While some small percentage |

Hog Fuel

During the interview portion of this investigation, potential purchasers of

hog fuel were contacted on the Olympic Peninsula. Purchasers of hog fuel burn

this ground wood material to generate steam and electricity generally to provide

these resources for use in on-site manufacturing processes. The largest purchasers

of hog fuel on the Olympic Peninsula are paper making companies which are able

to mix hog fuel with sludge and liquor residuals from paper manufacture prior

to combustion in boiler systems. Representatives were interviewed from four

companies that purchase hog fuel. Three companies are paper manufacturers and

one produces panel products.

- Nippon Paper Industries USA CO., LTD, Port Angeles, WA. A manufacturer of paper products.

- Kply, Inc., Port Angeles, WA. A manufacturer of plywood products.

- Port Townsend Paper Corporation, Port Townsend, WA. A manufacturer of paper products.

- Grays Harbor Paper Company, Hoquiam, WA. A manufacturer of paper products.

All company hog fuel purchasers expressed concern about the wooly and unmanageable nature of cedar bark. All cedar bark must be removed from hog fuel or it can ball up and clog conveyors. Each company must have hog fuel sized appropriately for efficient transport through hog fuel conveyor systems. Most purchasers report that hog fuel should be ground to meet a 3 inch minus specification. Nippon can take 6 inch minus. Sizing requirements are important to minimize the tendency of wood waste to “bridge” and “rat-hole” in storage bins and at transfer points.

| Figure 14. Raw Shingle waste on the left compared to hogged shingle waste on the right. |

Fuel value of wood depends on the amount of heat energy that can be recovered. The amount of recoverable heat logically varies with moisture content and chemical composition. Moisture in wood evaporates, absorbs energy in combustion, and escapes in stack gases as heated water vapor. Fuel moisture is usually reported as a percentage of moisture content. Generally green wood can be expected to average around 50% moisture content. However, there can be variation in cedar that can range from below 40% to more than 60% moisture content. In 2000, near Taholah, WA., the Quinault Indian Nation excavated cedar waste from large outdoor stock piles that had accumulated from milling operations decades ago. Approximately 2400 green tons of material were hogged and shipped to Grays Harbor Paper in Hoquiam. The average moisture content for this material was 63% (Conway pers com). A separate study of old cedar waste conducted in Grays Harbor County and found that piles averaged 58% moisture content (Cascadia Consulting Group & Re-Sourcing Associates 1999). It is reasonable to expect that fresh cedar waste from active mill production should have lower moisture content than old piles exposed to years of rain. 50% moisture has been used in this investigation as a ball park estimator for conversion of cedar waste from green tons to dry tons.

Two compositional characteristics of cedar that affect its usefulness as hog fuel are density and oil content. Cedar is relatively less dense than and contains more oil than other species, causing it to burn hot and fast at average moisture content. Western red cedar has been found to have a higher BTU (British thermal unit)/ oven dry lb. (pound) than other Northwest species including Douglas-fir (Pseudotsuga menziesii) and western hemlock (Tsuga heterophylla) (Ince 1979). Some boiler operators suggest that, while cedar may burn too quickly in a 100% concentration, if it is added to a hog fuel mix at about 20% then the burn temperature is raised without speeding the burn, effectively yielding higher overall BTU values (Cascadia Consulting Group & Re-Sourcing Associates 1999).

Table 3. Heating values for the wood of some NW species in BTU/ovendry ton (Ince 1979).Western red cedar |

Douglas-fir |

Western hemlock |

Big leaf maple |

Red alder |

9,700 |

8,950 |

8,370 |

8,400 |

8,860 |

In order to better understand the costs associated with disposal of mill waste as hog fuel rather than combustion in non-compliant burners, information is needed for a number of factors. A waste test was designed and implemented from which data was collected to calculate waste-to-product recovery ratio, the speed at which waste develops during production, the acceptability of cedar waste by existing hog fuel consumers, and the cost of waste shipments. Premium Shingle Company, in Beaver, WA., volunteered the use of its mill for the test program. The existing burner was removed, the existing incline waste conveyer was modified, and a gravel road bed was installed such that a chip van could be located under the conveyor to receive mill waste. The van was stirred and moved as necessary by mill employees to best capture the developing waste from shingle production. To assure collection of undiluted production information, all waste that was collected was limited to the total production of one shingle saw for which daily usage of cedar cord wood and subsequent production of shingles was tallied. West Waste and Recycling, Inc. (WWR) volunteered the use of a live-bottom chip van for the duration of the production test. Periodically the van was hauled to Hermann Brothers Logging and Construction, Inc. (Hermann) chipping and grinding facility in Port Angeles. Hauling was done by WWR truck at a cost of $200 for the 100 mile round trip. At the Hermann yard, vans were unloaded and the cedar waste was ground into hog fuel (approximately 3” minus) for a $2/green ton charge to the cedar mill. Hogged material was shipped to Nippon Paper Industries USA Co., LTD. (Nippon) located at the base of Ediz Hook in Port Angeles. As a result of the test, Nippon has determined that cedar waste is acceptable for use in their boiler system if ground to 6 inch minus and all bark has been removed. Hermann recovers hog fuel payment from the purchaser (Nippon) to underwrite handling costs. Under this arrangement the cedar mill must pay the cost of trucking and the grinding fee. This is currently the only immediately available disposal option to replace waste burners.

Table 4 & 5 Cedar Waste Test ResultsCedar Waste Test Results |

||||||

| Load # | Date | Days |

Cords |

Net Wt |

Tons/cord |

Tons/day |

| 1 | 4/12/2005 | 7 |

12 |

35,420 |

1.48 |

2.53 |

| 2 | 4/23/2005 | 5.5 |

9.5 |

27,740 |

1.46 |

2.52 |

| 3 | 5/4/2005 | 7.5 |

12.75 |

32,480 |

1.27 |

2.17 |

| 4 | 5/16/2005 | 7.5 |

12.75 |

34,780 |

1.36 |

2.32 |

| Average Four Loads | 6.9 |

11.8 |

32,605 |

1.39 |

2.38 |

|

| Load # | Date |

Truck $/ton |

Hog$/ton |

Waste $/ton |

Waste $/cord |

%Waste $/Gross Sales |

| 1 | 4/12/2005 |

($11.29) |

($2.00) |

($13) |

($20) |

-2.48% |

| 2 | 4/23/2005 |

($14.42) |

($2.00) |

($16) |

($24) |

-3.04% |

| 3 | 5/4/2005 |

($12.32) |

($2.00) |

($14) |

($18) |

-2.31% |

| 4 | 5/16/2005 |

($11.50) |

($2.00) |

($14) |

($18) |

-2.33% |

| Average Four Loads | ($12.27) |

($2.00) |

($14) |

($20) |

-2.54% |

Tables 4 and 5 above display the results of the cedar waste test. When burners are removed and waste is collected in vans for shipment to Port Angeles where the material is hogged to purchaser specifications and then forwarded on to the purchaser, an average additional operations cost of $20/cord must be absorbed by the cedar mill. Expanded to reflect annual impact, this figure calculates to approximately 2.54% of total gross sales representing a total cumulative industry expense of between $154,633 - $279,341/year. Seen as an impact to individual mills, this annual cost would range from a low of $2,469 for the smallest mill with the low production assumption to a high of $73,162 for the largest mill with a high production assumption. These costs do not include the costs of shingle mill modifications to facilitate van loading, the costs of down time during mill modifications, the additional operational costs of extra employees to stir and move the vans, or the possible expense associated with van rental or purchase.

It would be correct to suggest that careful van loading to better maximize payloads should reduce trucking costs. However, van weights when hauled to town during this test were unable to be optimized due to operational challenges in scheduling for the mill and the trucker that are likely to occur under normal business conditions. To effectively maximize haul loads, mills would need to purchase a company truck and two vans such that one van could be collecting waste while the other is delivering to town. It is important to recognize as well that, for this test, no fee was charged for van use. Under more realistic circumstances, mills would need to purchase or rent vans which would increase waste disposal costs. Therefore, it is the conclusion of the investigators that the analysis developed from test data presented above is likely an accurate representation of cost magnitudes that can be expected for this waste disposal alternative.

| Figure 15. Chip van receiving shingle waste at Premium Mill in Beaver, WA. |

Other alternatives were also considered for removing waste for delivery as hog fuel. Simulations were conducted to estimate savings that might result from shipping raw waste to be hogged in Port Angeles in full size possum-belly (as opposed to live bottom) vans that were assumed to be filled to the maximum allowable gross weight for every shipment (30 tons net). Under such optimized circumstances with other test parameters held constant disposal costs could theoretically be reduced to $9/ton or $12/cord.

Another option would be for mills to install on-site hogging capabilities and recover the revenue from direct sales of hog fuel to Port Angeles purchasers. Current price quotes for hog fuel delivered to Port Angeles range from $6 – $16/GT depending upon quality, moisture content, and sales leverage. Western Wood Products Association (2004) reported flat hog fuel prices for the region since 2001 due to increased sawmill production and poor paper prices. The average hog fuel price for western Washington is expected to remain around $22/bone dry ton (BDT) for the foreseeable future. This price would be the equivalent of $11/ GT at 50% moisture content. Allen Logging Company and Portac Inc. are two large capacity sawmilling operations in the Forks area. Both companies produce chips and hog fuel as by-products of lumber production. These mills report that receipts from shipping hog fuel from Forks generally cover trucking costs but produce no net revenue. The cost of installation of hogging capabilities on a per mill basis appears to be somewhere between $30 - $50,000. Rental or purchase of vans and trucks would likely be needed as well, which could add another $30 - $50,000. These estimates assume used equipment purchases and do not include losses from installation down-time or costs associated with the need for additional employees.

An understanding of sales leverage is also important for an accurate evaluation of this alternative or other alternatives where it is assumed that small operations such as the cedar mills are to make individual sales arrangements with large volume hog fuel purchasers. Availability of market supplies/need for hog fuel ebb and flow resulting in times of surplus when the hog fuel purchasers “cut-off” their small volume suppliers. When mills ship waste to a large processing facility such as Hermann there is security that shipments will not likely be stopped when hog fuel is abundant. This would likely not be the case if small mills individually negotiate direct contracts with large paper mills.

A local waste disposal business has expressed interest in the establishment of a privately operated central grinding facility located in the Forks area close to the mills. Waste would be picked up from mills, hogged, and shipped to Port Angeles customers. Mills would be charged a per ton tipping fee. Freight costs plus profit would be captured by the waste company through sale of hog fuel to Port Angeles purchasers. The creation of such new waste disposal infrastructure could, depending upon the magnitude of the tipping fee, create a possibility for reduced waste disposal cost to mill owners. Such an operation would mean that individual mills would not need to purchase and install handling and grinding equipment. The cumulative costs of vans and trucks would also be reduced since duplicate equipment at every mill would not be needed. Capital investment costs for a centrally located facility would likely be several hundred thousand dollars. For example, the Portable tub grinder that Hermann operates (although arguably larger than may be needed for cedar mill waste) has a value of $500,000. Since the total cumulative cedar waste stream with all shingle mills in full operation is estimated to be approximately 3 vans/day, business volume may be inadequate to support a central facility fixed and variable operations costs. The local waste disposal business has placed this alternative under consideration pending the findings of this report.

A variation of the central facility theme might be to have the cedar mills stock pile waste temporarily pending periodic arrival of privately operated portable grinding equipment. Capital investments could be reduced if a central fixed facility would not be needed. Less investment in vans, dump boxes, or trucks would be needed as well. Waste, after being hogged, could be loaded by front end loader into an arriving van (total van purchases could be reduced to three or four and the need for dump boxes would be eliminated). The waste removal company would work on a contract basis with mills. The potential volume of business would still be a concern and there are other problems with this alternative that must be considered as well; many mills lack needed space and don’t have front end loaders.

Another possible utilization strategy for hog fuel would be for engineered fill applications. Cedar hog fuel has been shown to be useful in road construction projects as a back fill for bank stabilization or where roads must cross bogs or marshes. The WA Department of Transportation, the Washington Department of Natural Resources, and the Forest Service have all successfully used hog fuel for off-highway road building (Cascadia Consulting Group and Re-Sourcing Associates 1999). However, no consistent market for this hog fuel application was found during this investigation. Problems that may limit this use of hog fuel in the future include concerns over spontaneous combustion, decay slumping, and leachate that may be harmful to salmon.

Existing Choices Not Encouraging

A suite of waste disposal alternatives, as was requested by the Clallam County

Economic Development Council, has been presented. None of these options appear

to represent an alternative likely to ensure the viability of the area shingle

mills. Further, financial support for modifications to mills may or may not

be available and is certainly not accessible by July 2005. Table 6 is presented

below to show the sensitivity of debt burden to variations in principle and

interest. The apparent least cost for modest mill modifications would result

in $1000/month payments for 5 years.

Comparisons of debt burden (monthly payment) for 5 year notes |

||

Interest rate |

Principle |

Monthly Payment |

6.50% |

$50,000 |

$978.31 |

6.50% |

$100,000 |

$1,956.62 |

10% |

$50,000 |

$1,062.36 |

10% |

$100,000 |

$2,124.71 |

Results from the Premium Cedar waste test show monthly estimated costs/mill results that distributed to other mills will range from a low of $269 (smallest mill with low production assumption) to a high of $6018 (largest mill with high production assumption). Installation of new hogging or incineration equipment likely would cost each mill a minimum of $1000/month and could be much higher.

The only immediately available option is to take the raw waste to Port Angeles where the material is hogged and then forwarded on to the purchaser, creating an average additional operations cost of $20/cord that must be absorbed by the cedar mill. Expanded to reflect annual impact, this figure calculates to approximately 2.54% of total gross sales representing a total cumulative industry expense of between $154,633 - $279,341/year. Seen as an impact to individual mills, this annual cost would range from a low of $2,469 for the smallest mill with the low production assumption to a high of $73,162 for the largest mill with a high production assumption. These costs do not include the costs of shingle mill modifications to facilitate van loading, the costs of down time during mill modifications, the additional operational costs of extra employees to stir and move the vans, or the possible expense associated with van rental or purchase.

Whether or not some or all of the mills will be able to absorb the costs associated with options for disposal of waste that have been presented above remains an unknown. However, there are some logical conclusions given the evidence. Mills that can move to better locations closer to Aberdeen where disposal costs are much more affordable may be well advised to do so. Mills that are well capitalized and now are forced to consider the wisdom of the cedar business as compared to other investment alternatives logically may not choose cedar. Mills that are very small marginal operations may have no choice but to close. Mills that do remain will endure waste cost burdens unique to Clallam County that, at the very least, will give comparative advantage to Grays Harbor mills as they compete for scarce raw material. Landowners wishing to sell cedar salvage will loose value in part or entirely as the local industry downsizes and operating costs increase. Marginally employable workers will loose jobs and the local economic/tax contributions of a ten million $ plus local industry will likely be reduced or eliminated. However, the investigation team found that there may be more to this story.

The Case for a Broader View

In addition to social and economic impacts to the Forks community, a potential

loss of shingle milling infrastructure may represent a lost opportunity to

reduce air pollution. We have seen that cedar waste that has been hogged

has real market value. When delivered to Port Angeles the market is $6-16/

GT. The regional average has been shown to be $11/GT. The problem for cedar

mill owners is that current value is less than cost. Handling and freight

charges consume all of the available value and result in substantial disposal

charge. But is this limited-access market price/ton the only measure of hog

fuel worth? We can think about the value of hog fuel another way; to the

hog fuel purchaser the utility value has to be greater than the market price

($11/GT). The utility value of cedar hog fuel can be characterized as having

a price just less than that of the locally available least-cost fuel alternative.

Described simply, this value represents a utility comparison of fuel alternatives

in dollars per unit of energy output which are often measured in British

Thermal Units (Btu). A recent Forest Service study cites an interesting cost/Btu

comparison for alternative fuels based upon 2003 data (Bergman and Zerbe

2004).

Fuel |

Oil |

Natural Gas |

Coal |

Wood |

$/Million Btu |

$2.25/MM Btu |

$5.60/MM Btu |

$1.27/MM Btu |

$1.20-2.70/MM Btu |

The wood cost used in this table was provided by McNeil Power Station, a 50 megawatt (MW) wood-burning electricity generation station in Burlington, Vermont. The McNeil plant has generated electricity exclusively from wood for more than 20 years. The delivered value of wood fuel represented in the above table was $10 - $23/ green ton. At the high fuel price of $23/green ton, McNeil was producing electricity profitably for the New England market at approximately $0.064/kilowatt hour (kWh).

With growing concerns about global warming, there is an international sense of urgency to reduce consumption of fossil fuels by shifting to clean and renewable energy sources. The 2002 U.N. World Summit on Sustainable Development (Johannesburg Summit) adopted a Political Declaration and a Plan of Implementation, which includes “Clean Energy” as one of its five most important policy directions for the world (World Summit on Sustainable Development 2002). The U.S. State Department followed this directive with its implementation of a $42 million Clean Energy Initiative (U.S. Dept. of State 2002). U.S. domestic energy policy has followed similar direction with legislated incentives and tax credits for renewable energy development (Sissine 2005, Database of State Incentives for Renewable Energy 2005). The State of Washington also provides incentives and premiums for expansion of renewable energy (Database of State Incentives for Renewable Energy 2005). The Clallam Public Utility District, like most energy providers, now offers “green” electricity to those consumers willing to spend a little extra on their power bill to protect the environment. With all of this local-to-global focus on renewable energy, shingle waste (biomass) should be a valuable resource. Biomass-to-energy is the second largest source of renewable clean energy that is produced in Washington. Hydroelectricity is first but, unlike biomass-to-energy, has little potential for expansion.

Morris (1999) in a National Renewable Energy Laboratory Report entitled “The Value of the Benefits of U.S. Biomass Power” calculates the cumulative market and non-market values of biomass power by suggesting estimates of value for many factors normally not considered in hog fuel accounting such as reduced pollution, landfill savings, energy diversity, rural employment, and others. Morris estimates a broader value of biomass power at $0.114/kWh. Morris’ numbers indicate that the utility value of cedar hog fuel is far greater than the per ton price in Port Angeles.